Heat Input, Cooling Rate, And Metallurgical Control

Laser welding is inherently a low heat input, high cooling rate process, which is one reason it’s so effective for stainless steel. But “low heat” is not automatically “good” — the wrong heat input or cooling profile can lead to incomplete fusion, excessive ferrite, or microstructural defects that compromise both strength and corrosion resistance. By managing laser power, travel speed, beam focus, and filler selection, welders can control not just bead shape, but the metallurgy itself.

Keep Heat Input Low — But Not Too Low

· Why low heat is good:

1. Reduces distortion and residual stress, especially important in thin austenitic sheets with high thermal expansion.

2. Minimizes heat tint and oxide formation, reducing the need for post-weld cleaning.

· Why too low is bad:

1. Insufficient penetration and lack of fusion defects.

2. Excessively rapid solidification can trap gases and increase porosity.

3. In some grades, ultra-fast cooling can push the microstructure toward brittle or unbalanced phases.

· Control levers:

1. Power (W):higher power deepens penetration but risks overheating in thin sections.

2. Travel speed (mm/s):faster travel reduces total heat input but can cause fusion issues.

3. Spot size (mm):smaller spots concentrate energy; larger spots broaden the bead but reduce penetration depth.

· Rule of thumb: Monitor energy per unit length (J/mm) — aim for the minimum value that achieves full fusion without defects, typically 30–60 J/mm for thin sheets, higher for thicker duplex sections.

Ferrite In Austenitic Welds

· Metallurgical background:

1. Fully austenitic solidification is prone to solidification cracking because it cannot absorb low-melting-point impurities at grain boundaries.

2. Introducing 3–8% delta ferrite in the weld mitigates this by providing a “sink” for impurities.

· Laser-specific risks:

1. High cooling rates can freeze in the solidification structure before ferrite has time to form, increasing crack risk in certain alloys.

· Control methods:

1. Use slightly over-alloyed filler (ER308L, ER316L) to promote ferrite.

2. Avoid excessively high travel speeds on sensitive grades.

3. Verify ferrite content with a ferritscope in critical applications (especially food-grade and cryogenic service).

Interpass And Preheat

· Interpass temperature:

1. For most austenitic grades: keep <150 ℃ to avoid chromium carbide precipitation (sensitization), which lowers corrosion resistance.

2. For duplex grades: keep <150 ℃ to prevent secondary phase precipitation and to control ferrite–austenite balance.

· Preheat:

1. Rarely required for austenitic or duplex grades.

2. Essential for martensitic and precipitation-hardening stainless steels (100–300℃) to avoid quench cracking and hardness spikes in the HAZ.

3. It should be applied uniformly to avoid differential expansion.

· Laser-specific note: Single-pass laser welds rarely exceed interpass temperature limits, but in multipass hybrid laser–arc welds, heat accumulation can become an issue.

Duplex Phase Balance

· Target: ~50% ferrite / ~50% austenite in the weld zone.

· Laser welding risk:

1. High cooling rates tend to lock in excess ferrite (>65%), leading to reduced impact toughness and pitting corrosion resistance.

2. Overheating can also cause austenite reformation to be incomplete.

· Control strategies:

1. Use Ni-rich fillers (e.g., ER2209 for 2205 duplex) to drive austenite formation.

2. Slightly increase heat input compared to austenitic welding — this slows cooling enough for phase transformation without risking grain growth.

3. Keep interpass temperature low to prevent sigma phase formation.

· Verification: In high-spec industries (offshore, desalination), ferrite content is routinely checked after welding using portable ferrite measurement equipment.

In laser welding stainless steel, heat input is a metallurgical tool — too much causes distortion and sensitization, too little causes lack of fusion, excessive ferrite, or cracking. Austenitic welds require small amounts of ferrite to avoid hot cracking, martensitic and PH grades may need preheat, and duplex steels demand careful control of heat input to preserve phase balance. The fastest way to ruin stainless steel’s corrosion resistance is to ignore the relationship between laser parameters, cooling rate, and microstructure — the best way to preserve it is to control them deliberately.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

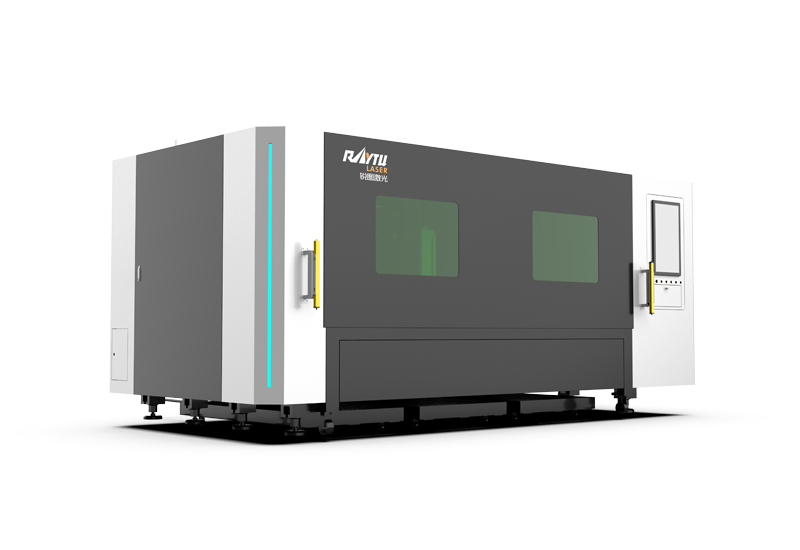

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR