Shielding Gas Strategy

In stainless steel laser welding, shielding gas is not just about keeping oxygen away from the molten pool—it directly influences weld penetration, bead shape, spatter levels, and final corrosion resistance. The concentrated nature of the laser beam means the molten pool solidifies quickly, so gas selection and delivery must be precise. Poor shielding leads to visible oxidation (heat tint), porosity, nitrogen embrittlement (in certain grades), and reduced service life in corrosion-critical applications.

Argon (Ar)

Properties: Inert, density 1.38 g/L (heavier than air), low thermal conductivity (~1.4x lower than helium).

Performance in Laser Welding:

Excellent coverage of the weld pool due to its weight, forming a stable protective blanket even at moderate flow rates.

Produces smooth, bright welds in austenitic and ferritic grades with minimal post-weld cleaning.

Lower thermal conductivity can lead to slightly reduced penetration depth compared to helium, but this can be offset by increasing laser power or reducing travel speed.

Common Uses: High-quality cosmetic welds, thin sheet applications, food-grade stainless products.

Helium (He)

Properties: Inert, density 0.178 g/L (lighter than air), very high thermal conductivity (~6x that of argon).

Performance in Laser Welding:

Increases heat input into the weld pool by improving laser coupling efficiency, especially useful for thicker stainless sections and deep keyhole welding.

Produces narrower but deeper welds at the same laser power compared to argon.

Improves escape of trapped gases, reducing porosity in high-speed welds.

Considerations: Because helium is light, shielding coverage is less stable, and higher flow rates (often 1.5–2× argon’s) are required. It is also significantly more expensive.

Common Uses: Deep penetration welds, heavy-gauge stainless, high-speed automated production lines.

Nitrogen (N2)

Properties: Technically inert in austenitic stainless welding, density 1.25 g/L, thermal conductivity between Ar and He.

Performance in Laser Welding:

In austenitic grades, nitrogen can stabilize the austenitic phase, improving pitting and crevice corrosion resistance (critical for marine and food processing applications).

Cost-effective alternative to helium for certain penetration gains.

In ferritic, martensitic, and duplex steels, excess nitrogen absorption can lead to nitrides, causing embrittlement and reduced corrosion resistance.

Considerations: Must be matched to the stainless steel family to avoid negative effects.

Mixtures

Ar–He: Commonly 75–90% Ar with 10–25% He for deeper penetration without losing argon’s coverage stability.

Ar–N2: Often 98% Ar with 2% N2 for pitting resistance enhancement in 304L/316L stainless.

Ar–He–N2: Used in specialized industries (e.g., offshore, desalination) where both deep penetration and corrosion resistance are critical.

Laser-Specific Note: Gas mixing affects beam-plasma interaction in high-power keyhole mode welding—too much helium or nitrogen can destabilize the plume if flow is turbulent.

Flow and Coverage

Flow Rates:

Argon: Typically 10–20 L/min for handheld or robotic systems.

Helium: Often 15–30 L/min to compensate for low density.

Nitrogen or mixtures: Set according to dominant gas density—lighter gases require higher flow.

Nozzle Design: Wide, conical nozzles for spot and fillet welds; coaxial gas delivery for consistent protection in robotic automation.

Trailing Shields: Extend protection several centimeters beyond the weld pool, preventing oxidation during cooling—critical for stainless steels where even light oxidation can damage corrosion resistance.

Gas Purity: Use ≥99.99% purity to avoid microscopic contamination. Even 0.1% oxygen can cause visible discoloration in high-spec stainless welds.

Shielding gas selection in laser welding stainless steel is a balance between penetration, protection, and cost. Argon gives stable coverage and a clean bead appearance, helium boosts penetration and speed, and nitrogen can enhance corrosion resistance in the right alloys. Mixtures allow fine-tuning, but purity, flow rate, and delivery method are just as important as gas type. Poor shielding compromises both weld quality and the stainless steel’s long-term performance—making gas strategy a critical part of every laser welding setup.

Filler Metal (When and Why)

Laser welding of stainless steel is often performed autogenously—without filler metal—because the process can produce narrow, deep fusion welds at high speed. However, there are many cases where adding filler wire is not just helpful, but essential for ensuring mechanical integrity, controlling microstructure, and compensating for production realities. The small molten pool in laser welding makes filler addition more sensitive than in arc welding, so its use must be deliberate and precisely controlled.

Crack Control

Metallurgical Reason: Certain stainless steels solidify in ways that make them prone to hot cracking or solidification cracking, especially when weld metal ferrite content is too low. This is common in fully austenitic welds, which lack ferrite to absorb impurities like sulfur and phosphorus.

Filler Metal Role:

Introduces alloying elements (like chromium and molybdenum) to slightly increase ferrite content (often targeting 3–8% ferrite for austenitics).

Softens the solidification path, reducing stress concentration at grain boundaries.

Helps avoid brittle martensitic transformation in susceptible grades (e.g., martensitic or precipitation-hardening types).

Example: Welding 316L with ER316L filler to maintain corrosion resistance but add ferrite for crack resistance.

Dissimilar Joints

Challenge: Different metals or stainless steel grades may have incompatible thermal expansion rates, corrosion potentials, or metallurgical reactions. Direct fusion without a buffer layer can result in brittle intermetallic compounds.

Filler Metal Role:

Acts as a metallurgical “bridge” between incompatible base metals.

Controls dilution, preventing excessive carbon pickup from carbon steels or nickel segregation in Ni-based alloys.

Example: ER309L or ER309Mo filler when joining 304L stainless to mild steel, creating a graded chemistry that resists cracking and corrosion.

Gap Bridging and Profile Shaping

Challenge: Laser welding tolerates extremely small gaps (<0.1 mm in sheet metal). In mass production, maintaining this precision consistently can be difficult.

Filler Metal Role:

Provides molten metal volume to fill gaps without undercut or incomplete fusion.

Allows intentional shaping of bead profile for strength (e.g., slightly convex bead for fatigue resistance).

Prevents collapse in thin edge joints where heat input alone would be insufficient.

Example: In automotive exhaust fabrication, ER308L filler may be added to close fit-up gaps in thin tube-to-flange welds while maintaining smooth flow surfaces inside the tube.

Duplex Stainless Steels

Metallurgical Challenge: Duplex grades (e.g., 2205) require a balance of ~50% ferrite and 50% austenite for optimal mechanical and corrosion properties. The rapid cooling of laser welding can leave excess ferrite.

Filler Metal Role:

Provides nickel-rich composition to promote austenite formation in the weld metal during solidification and cooling.

Prevents reduced toughness and pitting corrosion that occur with high ferrite content.

Example: ER2209 filler restores phase balance in 2205 duplex welds made under high-speed laser welding conditions.

Process-Specific Considerations

Wire Feed Accuracy: In laser welding, the filler wire must be precisely aligned with the laser focal spot. Even slight misalignment can cause incomplete fusion or asymmetrical beads.

Wire Diameter: Smaller diameters (0.6–1.2 mm) are preferred for thin sheet work; larger wires may be used in heavy sections with multi-kilowatt lasers.

Feeding Orientation: Can be coaxial (in-line with beam) for symmetrical welds or side-fed for improved visibility and control in manual systems.

Shielding Gas Matching: Shielding must protect both molten pool and filler wire tip—especially important when using nitrogen for austenitic stabilization or helium for penetration boost.

The right filler alloy—fed with precision and paired with the correct shielding strategy—ensures that welds meet both mechanical and corrosion resistance requirements, even in the most demanding applications.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

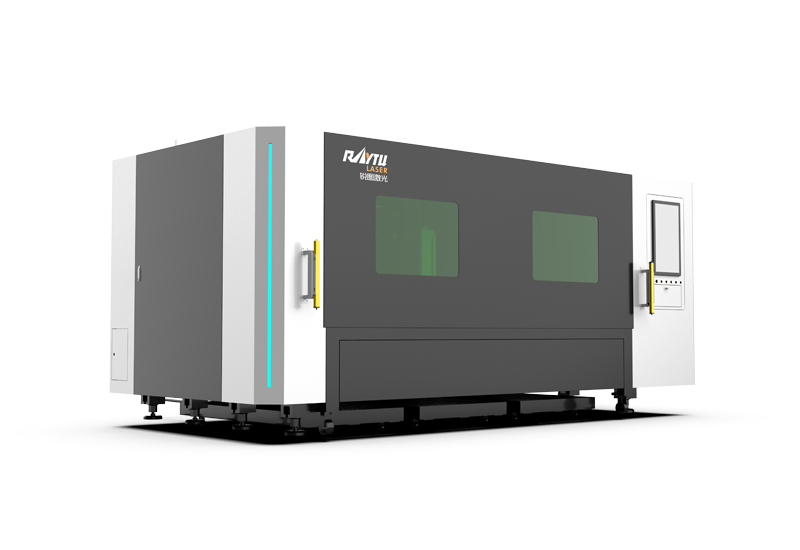

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR