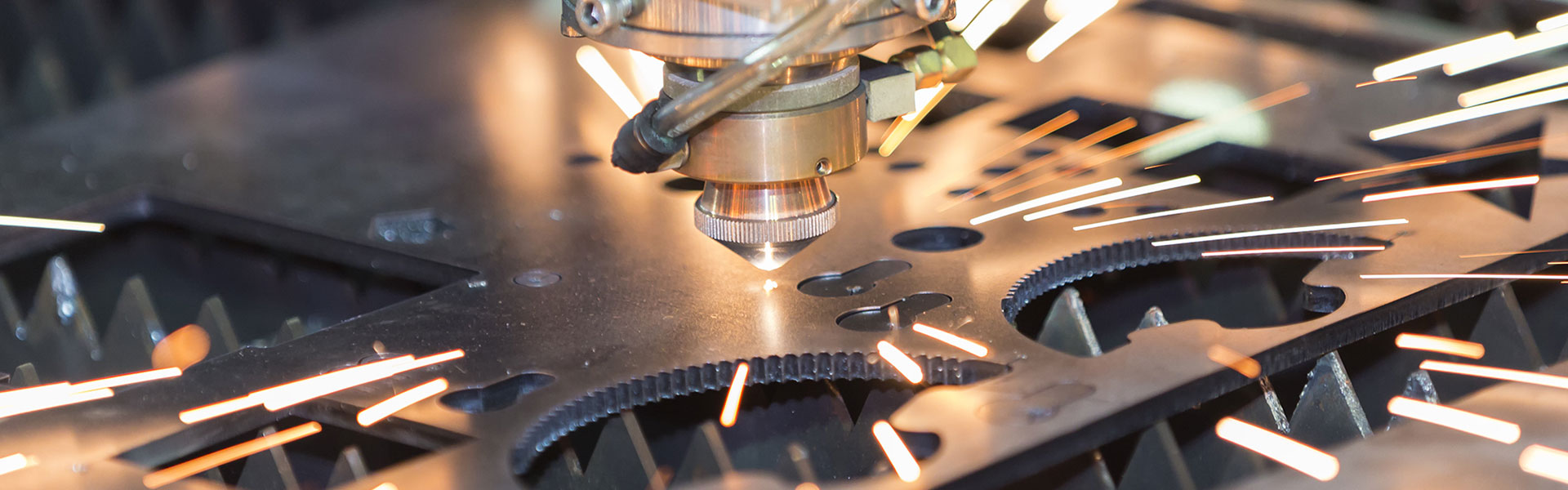

Equipment and Setup

Laser welding stainless steel requires carefully matched equipment to ensure stable performance, high-quality welds, and consistent production. The right combination of laser source, beam delivery system, motion control, and shielding equipment determines how efficiently the process runs and how clean the welds appear.

Laser Source

Types:

Fiber lasers: High efficiency, excellent beam quality, minimal maintenance, suited for both fine and deep-penetration welding.

Disk lasers: Stable beam quality over longer focal lengths, good for larger work envelopes.

Nd:YAG lasers: Older solid-state technology, still used for specific applications where pulse control is needed.

Key Considerations: Output power, beam quality (M²), and wavelength all affect penetration depth, weld speed, and joint type suitability. Fiber lasers are now dominant for stainless steel due to their efficiency and reliability.

Beam Delivery and Optics

Fiber Optic Delivery: Allows flexible routing of the beam from the source to the welding head with minimal loss.

Optics & Focusing Lenses: Determine spot size and focal position—critical for controlling penetration and minimizing distortion.

Protective Windows: Shield optics from spatter and smoke contamination; must be kept clean for consistent results.

Adjustable Focusing: Some systems allow dynamic focus changes for switching between deep penetration and surface welding.

Motion System

Robotic Arms: Provide high precision, flexibility, and automation for complex weld paths.

Gantry or Linear Systems: Offer stability and repeatability for large-scale or high-speed production lines.

Accuracy Requirements: Laser welding demands positional accuracy within fractions of a millimeter, especially for narrow beads.

Wire Feed and Wobble

Wire Feed: Used when filler material is required to bridge gaps, improve mechanical properties, or match corrosion resistance. Wire feeders must maintain precise speed to avoid over- or under-filling.

Wobble Welding: Oscillates the beam to widen the weld bead, improve gap tolerance, and reduce porosity. Adjustable wobble patterns and frequencies help optimize fusion in varying joint geometries.

Shielding and Trailing Shields

Primary Shielding: Inert gases like argon, helium, or mixtures protect the molten pool from oxidation. Helium improves penetration but increases cost; argon is more common for general stainless steel work.

Trailing Shields: Deliver shielding gas over the cooling weld bead, preventing heat tint and oxidation in stainless steel. Essential for aesthetic or corrosion-critical applications.

Gas Flow Control: Must be optimized to avoid turbulence that can cause contamination or porosity.

A successful stainless steel laser welding setup integrates a stable, high-quality laser source with precise beam delivery, accurate motion control, and effective shielding. Fiber lasers dominate due to their efficiency, while wobble welding and optional wire feed expand flexibility. Shielding and trailing shields are critical for protecting stainless steel’s corrosion resistance and appearance. By fine-tuning each element of the setup, fabricators can achieve clean, strong, and repeatable welds across a wide range of stainless steel applications.

Surface Preparation and Cleanliness

In laser welding stainless steel, preparation is not optional—it’s a performance-critical step. The laser’s narrow, high-energy beam interacts with a very small molten pool, which means that even microscopic contaminants can disrupt fusion, cause porosity, or damage the stainless steel’s corrosion resistance. The goal is to ensure a chemically clean, oxide-free, moisture-free joint with a tight mechanical fit before the first pulse of the laser.

Degrease First

Why it matters: Oils, cutting fluids, and fingerprints decompose under laser heat, releasing carbon and hydrogen gases that can cause porosity, undercut, or irregular bead formation. Carbon contamination can also locally reduce corrosion resistance.

Best practice:

Use lint-free wipes soaked in acetone or 99% isopropyl alcohol.

For heavily soiled surfaces, apply a dedicated vapor degreaser or alkaline cleaning bath before final solvent wiping.

Always degrease before any mechanical cleaning to avoid grinding oils into the surface.

Oxide Removal

Why it matters: While stainless steel’s passive chromium oxide layer is thin, thicker oxides from heat tint or laser cutting act as an insulating layer, disrupting beam absorption and causing incomplete fusion.

Best practice:

Mechanically: Use stainless-only brushes, fine abrasive pads, or precision blasting with non-contaminating media.

Chemically: Apply nitric acid– or citric acid–based pickling paste to dissolve heat-tint oxides without altering base metal properties.

For laser-cut parts, oxide removal is especially important along cut edges to ensure penetration.

Remove Films and Adhesives

Why it matters: Protective films, labels, or adhesive residues char under the laser, releasing fumes that can damage optics and cause weld porosity. Even tiny adhesive traces can cause gas pockets in the solidified weld.

Best practice:

Remove films well outside the weld zone to avoid adhesive transfer when peeling.

Use a solvent wipe to remove invisible residue.

Avoid abrasive methods that can embed glue particles into the surface.

Fit and Contact

Why it matters: Laser welding tolerates far smaller gaps than TIG or MIG welding—often less than 0.05–0.1 mm for sheet metal. Contaminants or burrs between surfaces prevent intimate contact, leading to incomplete fusion or keyhole instability.

Best practice:

Deburr edges after cutting or machining.

Use precision fixtures or clamps to maintain alignment.

Tack weld at strategic points to prevent separation during welding.

For automated lines, integrate optical sensors to check the gap size before welding.

Dryness

Why it matters: Water from cleaning agents or condensation introduces hydrogen into the weld pool, which can cause microcracks or porosity, especially in martensitic and PH stainless grades.

Best practice:

Air-dry cleaned parts fully, or use filtered, oil-free compressed air to speed up drying.

Store cleaned parts in a low-humidity environment before welding.

Avoid touching cleaned surfaces with bare hands to prevent recontamination.

Laser welding stainless steel leaves little margin for contamination. A rigorous preparation routine—starting with degreasing, followed by oxide removal, adhesive removal, ensuring tight fit-up, and guaranteeing dryness—protects the weld from porosity, fusion defects, and corrosion issues. These steps are standard practice in high-spec industries like aerospace, medical devices, and food processing, where the combination of strength, cleanliness, and corrosion resistance is non-negotiable.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

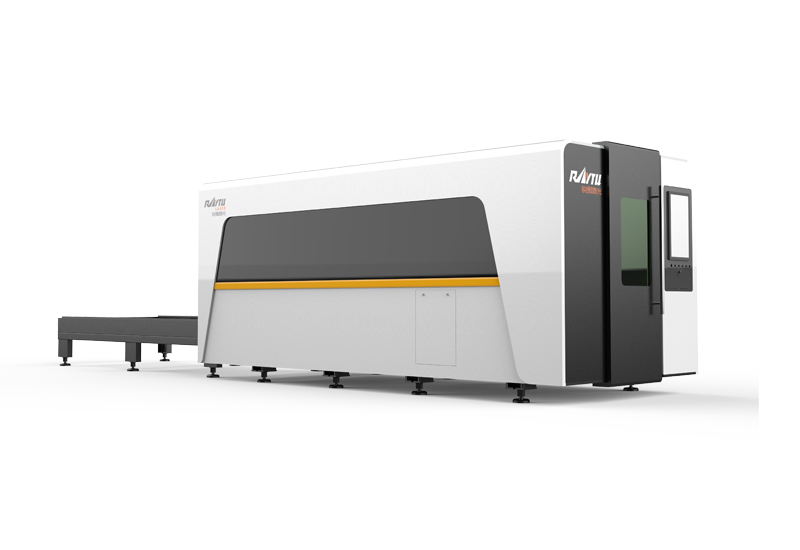

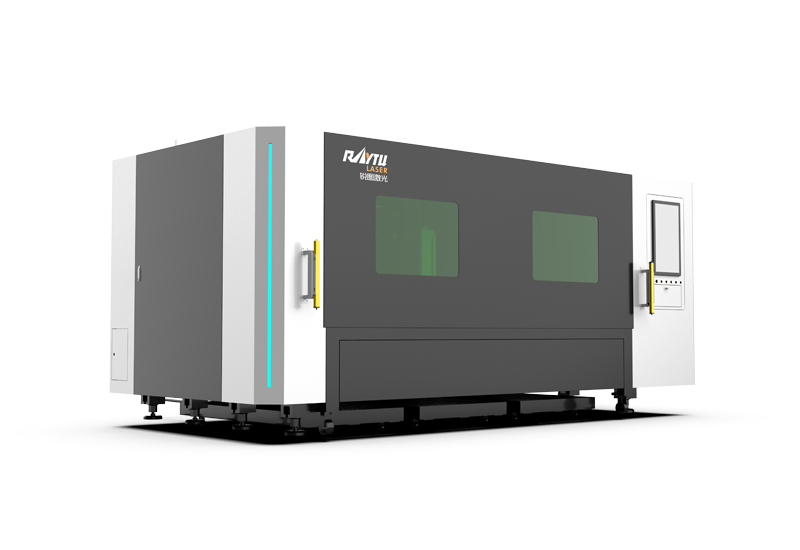

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

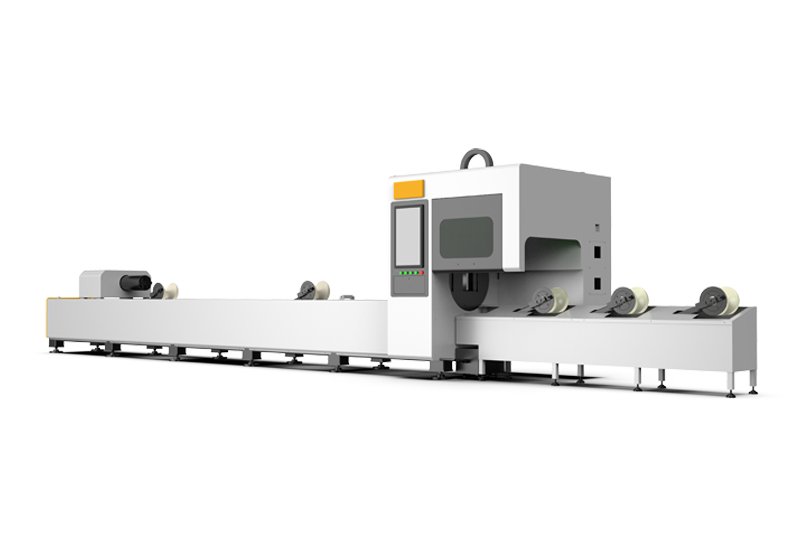

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

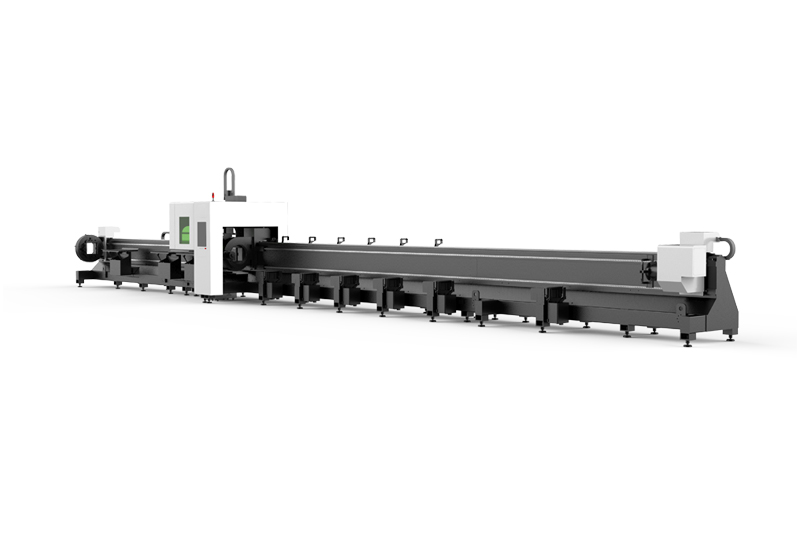

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR