Gas System

The gas system provides protective gases, typically high-purity argon or nitrogen, crucial for quality welds.

Maintenance Procedures

Check Gas Handling Components: Inspect all gas handling components, such as pressure regulators and solenoid valves, for any damage or gas leaks. Promptly address any issues to ensure safe and effective operation.

Water Chiller

The chiller is a crucial component of laser welder, responsible for providing cooling to both the laser and the welding head:

Maintenance Procedures

Cleaning the Heat Exchanger: Regularly clean the heat exchanger fins using a brush, followed by blowing compressed air to remove any debris, ensuring efficient heat dissipation.

Dusting the Condenser: Periodically remove dust from the condenser to maintain airflow and cooling efficiency.

Checking Water Levels: Regularly monitor the water level in the chiller tank. If levels are low, promptly add distilled or deionized water to avoid overheating.

Inspecting Electrical Connections: Periodically check the electrical terminals for dust accumulation and ensure they are clean and secure.

Examining Water Lines: Regularly inspect the water system for leaks and signs of aging in the pipes. Replace any damaged components immediately to prevent further issues.

Monitoring Water Quality: Regularly test the cooling water quality. If it becomes cloudy or its transparency decreases, drain the tank and refill with fresh coolant to maintain performance.

Cleaning Filter Cartridges: Regularly clear impurities from filter cartridges. Replace any damaged filters promptly to ensure the system operates efficiently.

Winter Maintenance

In winter, lower working temperatures may cause freezing in the water chiller, so extra care should be taken for maintenance during this time.

Install Heating Solutions: Adding air conditioning or heating systems can help maintain the environment temperature around 10°C (50°F), protecting equipment from extreme cold.

Run the Chiller Continuously: Keeping the chiller operational 24/7 ensures that water remains in a flowing state, preventing ice formation. This requires ensuring the facility has continuous power supply.

Add Antifreeze: Incorporate glycol antifreeze into the chiller system to lower the freezing point of the water mixture. Adjust the concentration based on the required freezing point.

Drain Water During Inactivity: If the equipment will not be used for an extended period or during power outages, make sure to drain the water from both the chiller tank and the laser to prevent freezing damage.

Electrical System

Check Circuit Breakers: Ensure that the main power circuit breaker and individual power supply breakers, including the emergency stop switch, respond promptly and effectively.

Verify Power Connections: Confirm that the laser machine’s power connections are correct.

Ensure Proper Capacity: Verify that the main and sub-circuit breakers (for the main unit, laser machine, air compressor, etc.) meet the specified capacity requirements.

Check Wire Gauge: Ensure that the diameter of the power, ground, and neutral wires meets the machine’s specifications and is not smaller than required.

Inspect Ground Connections: Verify that the ground connections of the power supply wires are secure and properly installed.

Examine Electrical Terminals: Check the reliability and security of all high-voltage wire terminals, especially at the input and output points of the power transformer. Ensure that all plugs and sockets are securely connected.

Monitor Voltage Stability: Regularly check the stability of the supply voltage to ensure consistent operation.

Maintain Cleanliness and Ventilation: Keep the electrical cabinet of the laser welder clean, organized, and well-ventilated.

Inspect Wiring Integrity and Safety: Regularly check all wiring for integrity and safety to prevent electrical hazards.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

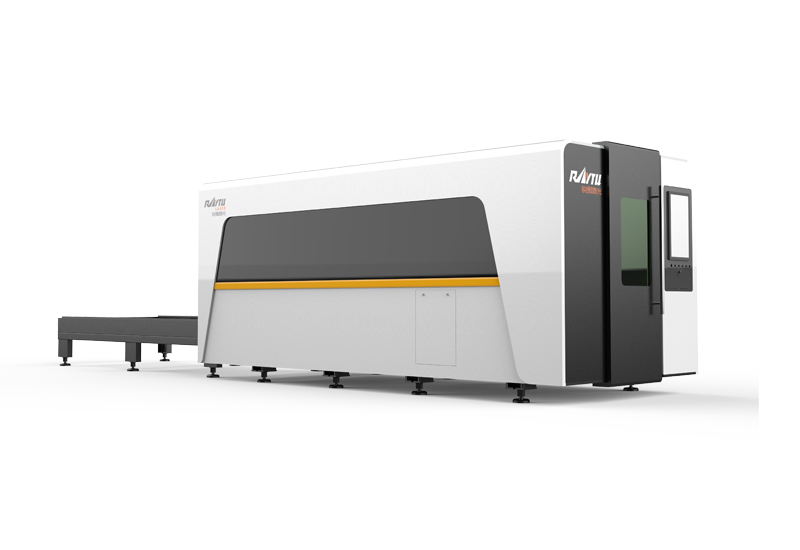

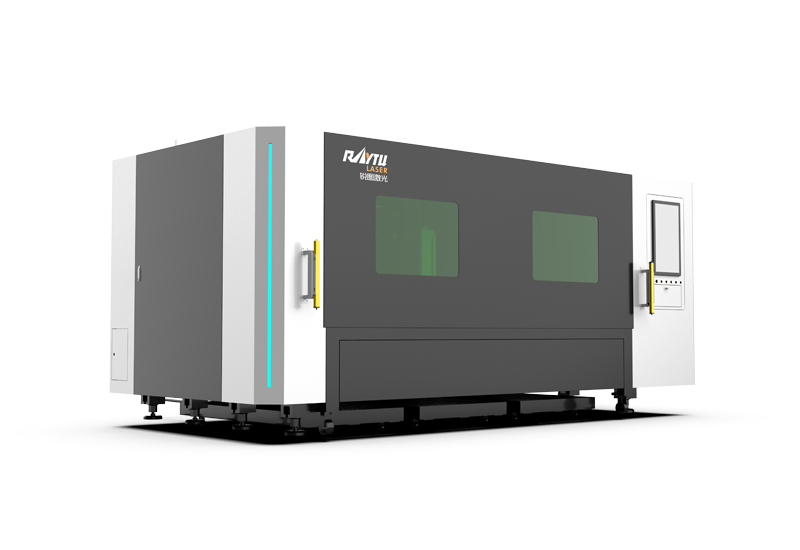

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

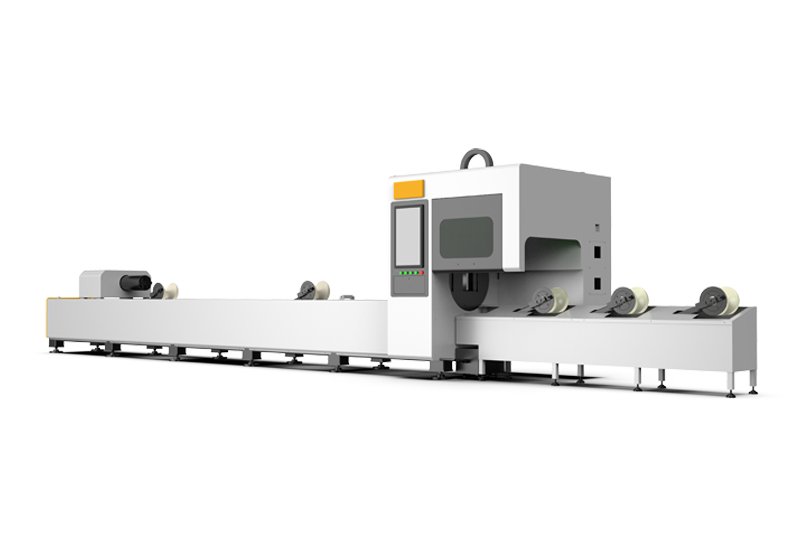

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

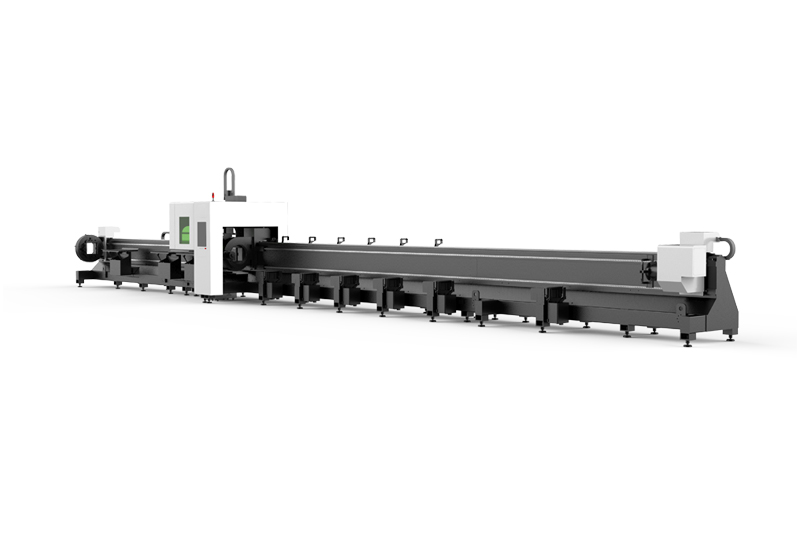

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR