Electrical System

Check Circuit Breakers: Ensure that the main power circuit breaker and individual power supply breakers, including the emergency stop switch, respond promptly and effectively.

Verify Power Connections: Confirm that the laser machine’s power connections are correct.

Ensure Proper Capacity: Verify that the main and sub-circuit breakers (for the main unit, laser machine, air compressor, etc.) meet the specified capacity requirements.

Check Wire Gauge: Ensure that the diameter of the power, ground, and neutral wires meets the machine’s specifications and is not smaller than required.

Inspect Ground Connections: Verify that the ground connections of the power supply wires are secure and properly installed.

Examine Electrical Terminals: Check the reliability and security of all high-voltage wire terminals, especially at the input and output points of the power transformer. Ensure that all plugs and sockets are securely connected.

Monitor Voltage Stability: Regularly check the stability of the supply voltage to ensure consistent operation.

Maintain Cleanliness and Ventilation: Keep the electrical cabinet of the laser welder clean, organized, and well-ventilated.

Inspect Wiring Integrity and Safety: Regularly check all wiring for integrity and safety to prevent electrical hazards.

Optical System

Precautions

Avoid Direct Contact: Do not touch the surfaces of optical lenses (such as protective lenses and focusing lenses) directly, as this can scratch the mirror surface.

Cleaning Restrictions: Never clean optical lenses with water, detergents, or similar substances, as they can damage the special coatings on the lens surface.

Proper Storage Conditions: Do not store lenses in dark, damp places, as this can cause aging of the lens surface.

Keep Lenses Clean: Lenses must be kept clean. Dust, dirt, or moisture can absorb laser energy and damage the coatings, affecting laser beam quality or even preventing the beam from generating.

Timely Replacement: Replace lenses promptly if they are damaged.

Care During Installation: When installing or replacing protective or focusing lenses, apply minimal pressure to avoid deforming the lens, which can negatively impact beam quality.

Lens Storage

Proper Storage: Ensure that optical lenses are stored correctly to maintain their quality.

Temperature Control: Store lenses in environments with temperatures between 10–30°C. Avoid placing them in freezers or similar conditions to prevent condensation, which can damage the lenses. Temperatures above 30°C can also affect the lens coatings.

Secure Environment: Keep lenses in a box and in a stable, vibration-free environment to prevent deformation that could impair their performance.

Laser Source

Power Line Inspection: Regularly check the power lines and ensure that the laser source is grounded. Use a multimeter to verify continuity between the laser housing and the ground (PE yellow-green wire) before powering on.

Control Line Compliance: Ensure that all control lines and voltages meet the manufacturer’s technical specifications. Non-compliance can lead to irreversible damage.

Fiber Protection: Handle fiber optics with care. Avoid bending or putting stress on the fibers to prevent damage.

Lens Cleaning: Protect the optical output head from dust. If cleaning is necessary, use 99.9% pure ethanol and lint-free swabs to avoid contamination.

Monitor System Functionality: During operation, continuously check the water, gas, and electrical systems for normal functionality. If any issues arise, power off the system immediately to diagnose the problem.

Fault Documentation: If any faults occur, document the time, symptoms, and operational status of the system before troubleshooting the cause.

Cooling System Maintenance: For long-term use, regularly clean the cooling water lines and keep the laser source clean. Replace the cooling water in the chiller periodically to maintain optimal performance.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

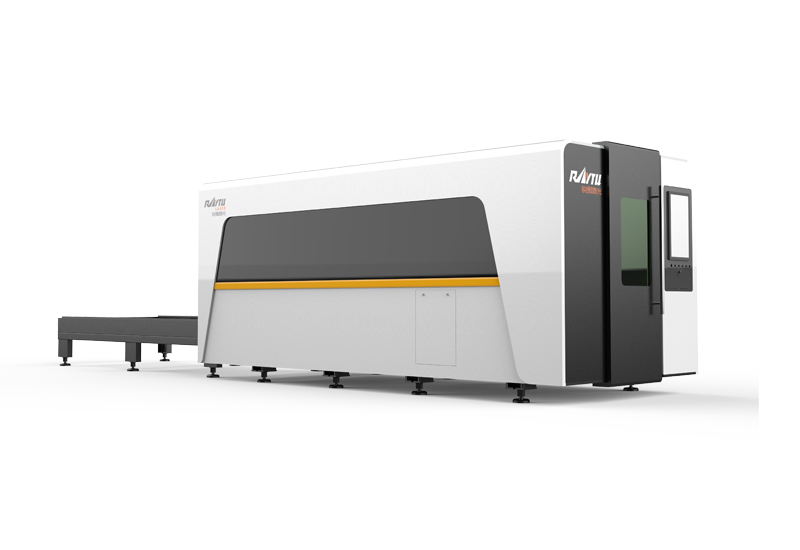

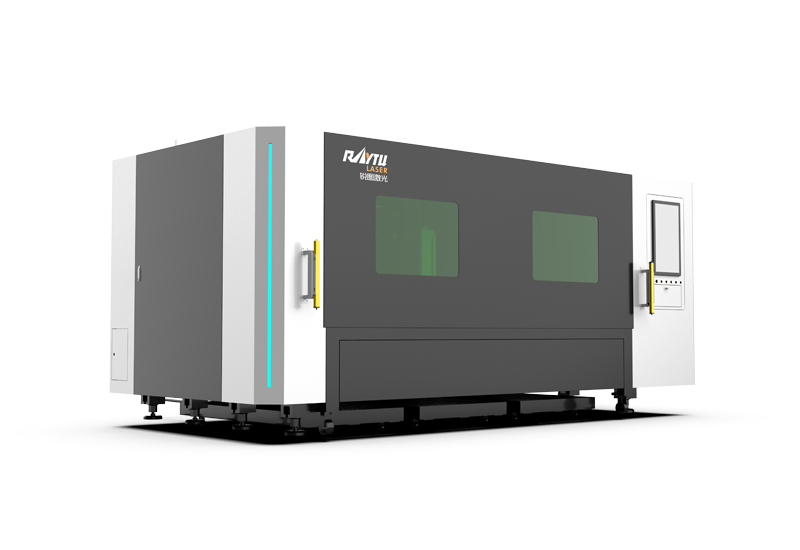

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

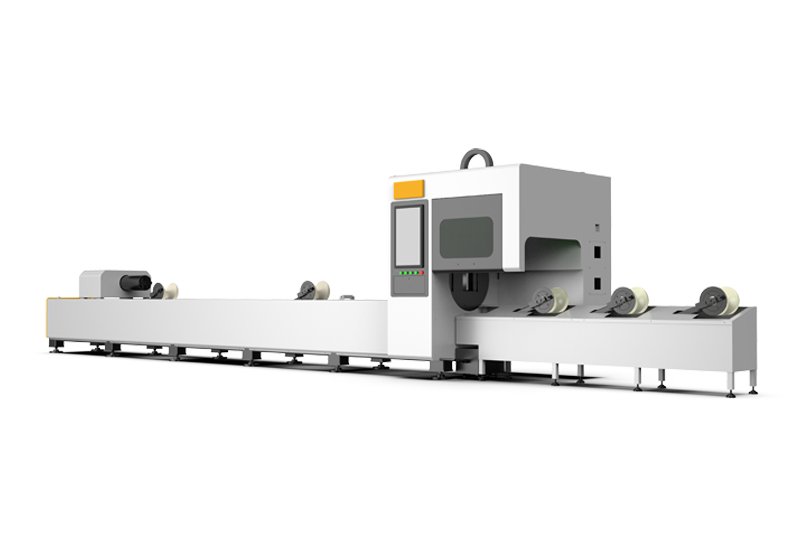

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

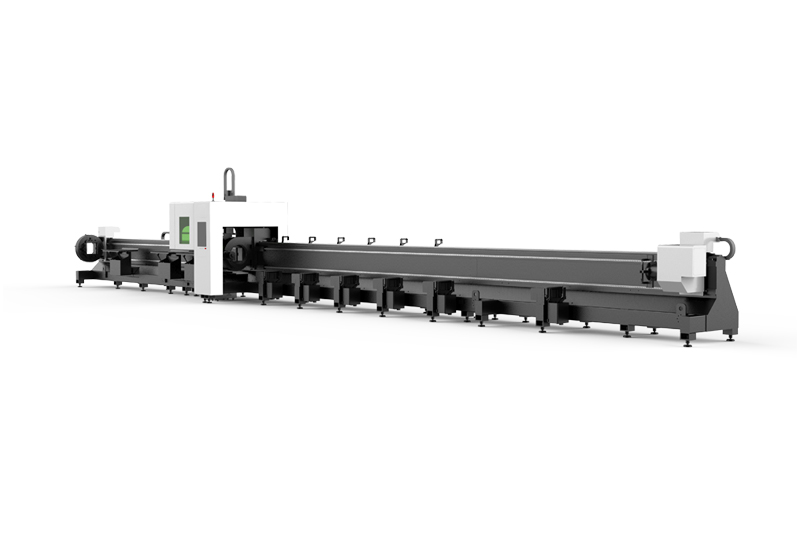

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR