+86-531-88239557

-

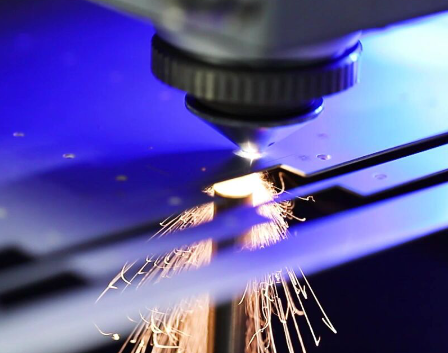

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

-

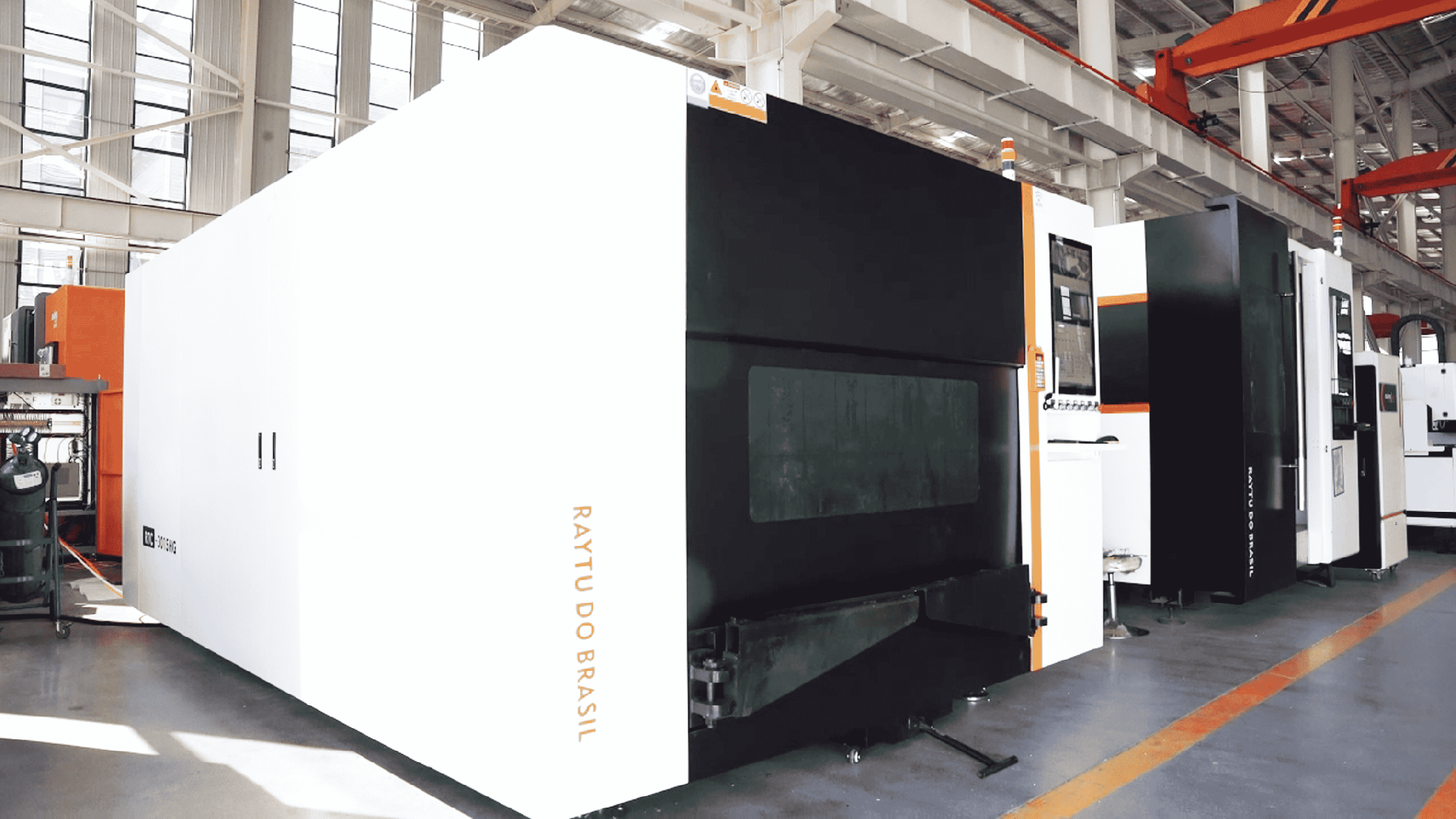

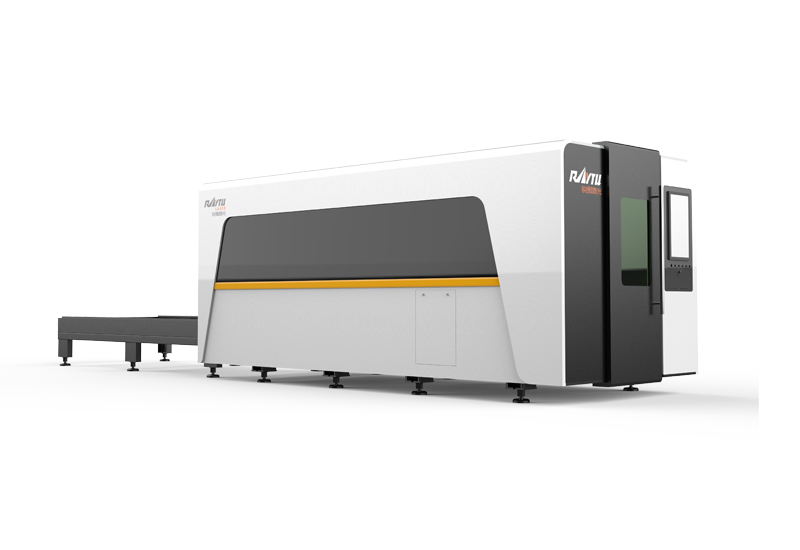

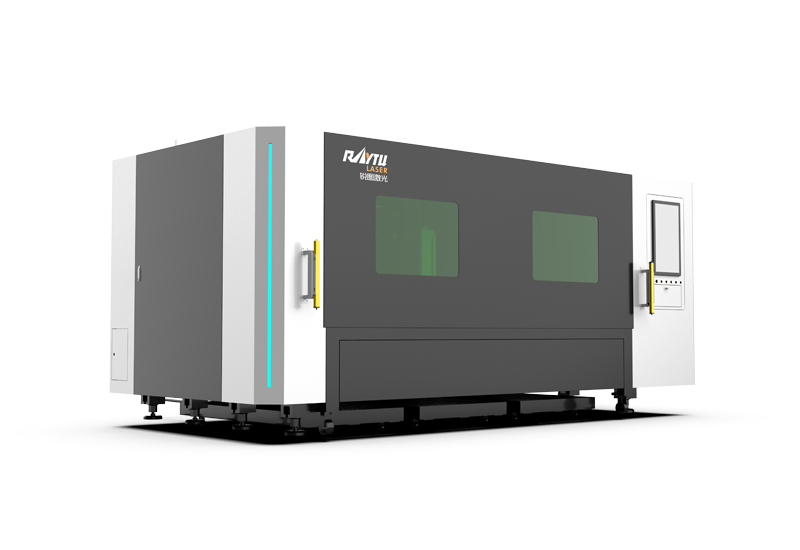

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

-

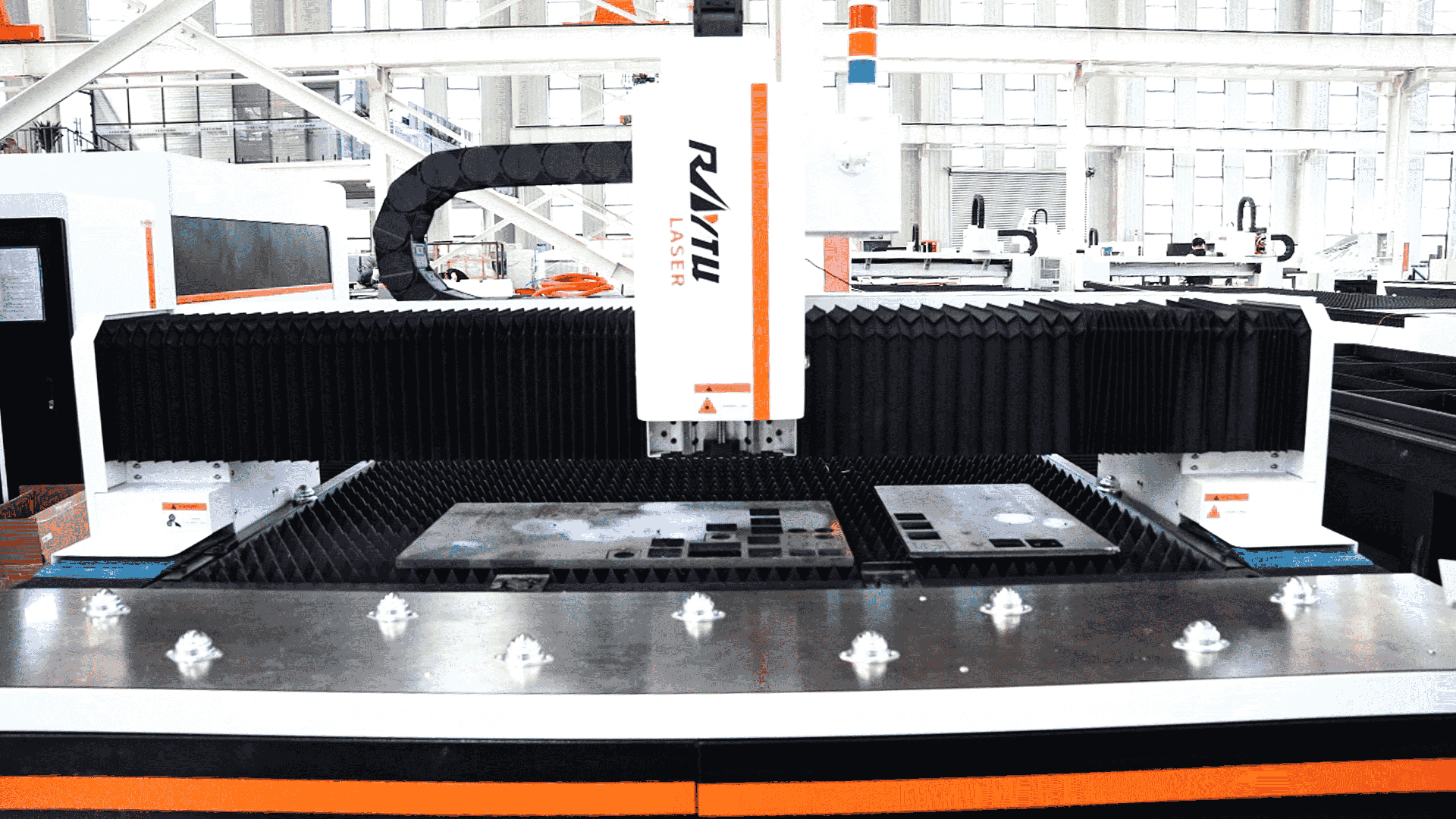

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

-

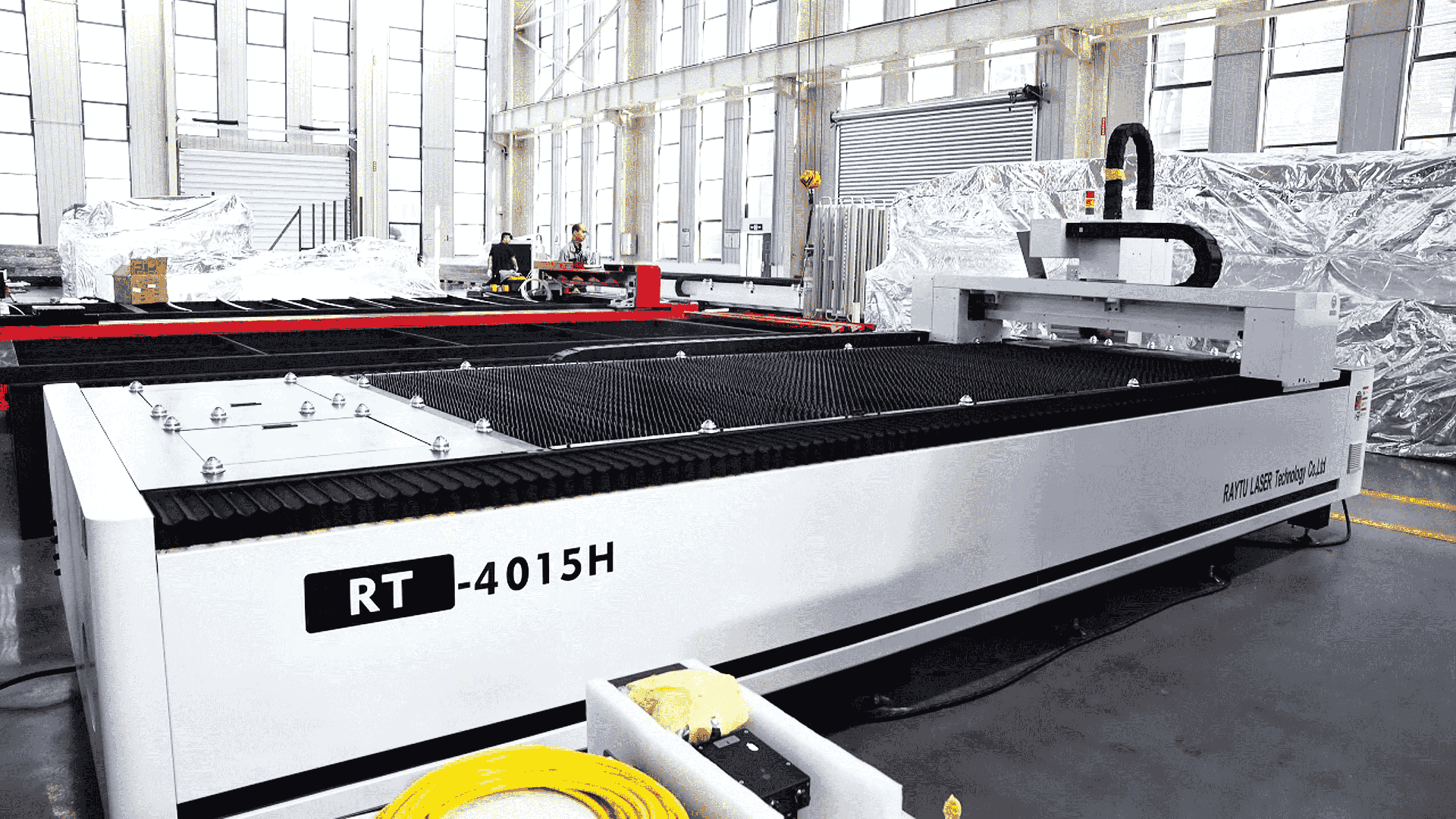

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

-

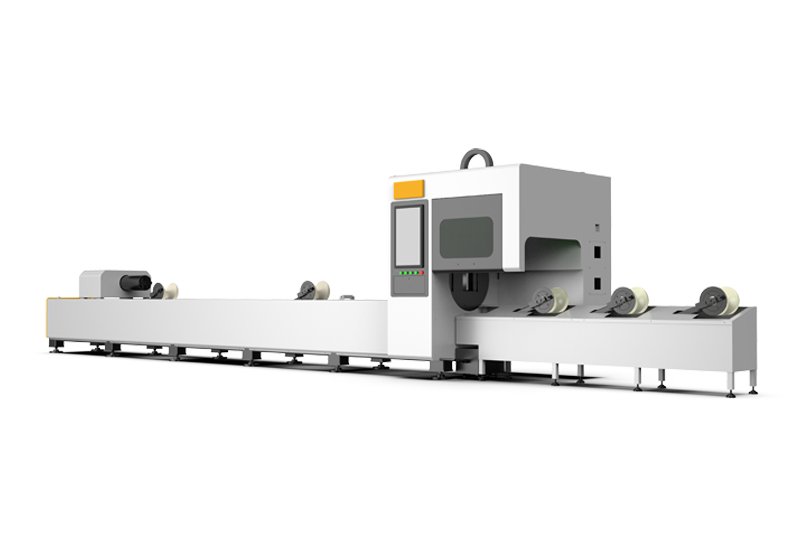

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

-

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

-

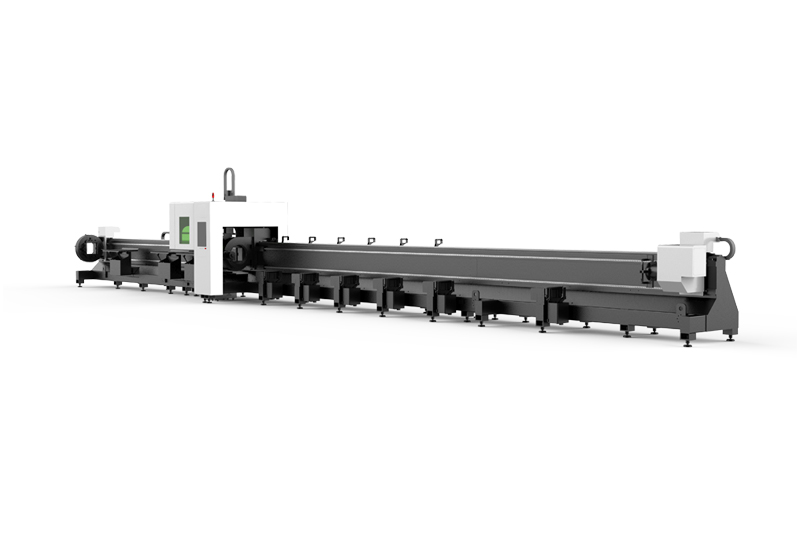

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

-

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR