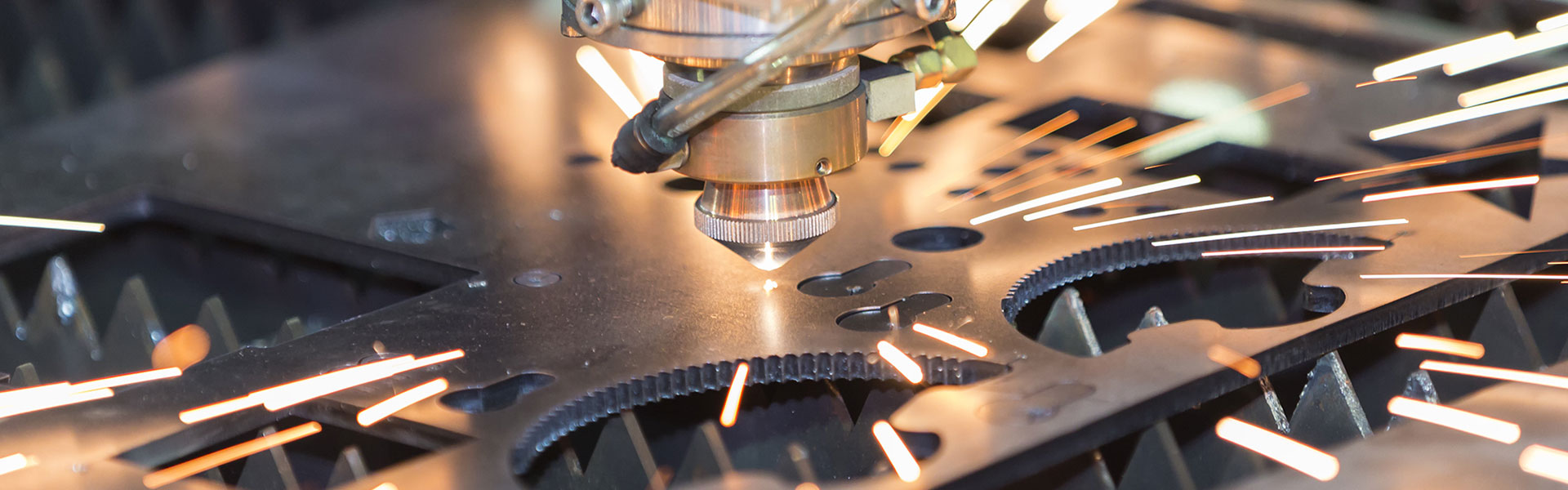

Equipment Architecture

Both laser rust removal and sandblasting rely on purpose-built systems designed to deliver consistent and effective results. However, their equipment architecture reflects the fundamentally different ways they operate. From the power source to the delivery mechanism and mobility features, each system is tailored for its specific method of rust removal. Understanding these components helps clarify what kind of setup, maintenance, and logistical support each method requires.

Core Power Unit

Laser Rust Removal: The core power unit in a laser rust removal system is the laser source, typically a fiber laser or solid-state laser. These units convert electrical energy into high-intensity, coherent light. Power ratings vary, ranging from 100W handheld systems to 6,000W+ industrial models. The power unit often includes integrated cooling systems (air or water) to prevent overheating and ensure continuous operation.

Sandblasting: In sandblasting, the core power unit is a compressed air generator or a centrifugal blasting wheel. For pneumatic systems, an air compressor generates the high-pressure airflow needed to propel abrasive particles. These units can be large and noisy, requiring fuel or electricity, and often include regulators to adjust pressure depending on the surface being cleaned.

Delivery Head

Laser Rust Removal: The delivery head is an optical scanning unit that focuses and directs the laser beam. It may be handheld for manual work or mounted on robotic arms or gantries for automated applications. The head contains precision lenses, galvanometer scanners for beam steering, and sometimes distance sensors to keep the beam correctly focused on the surface.

Sandblasting: The delivery head in a sandblasting system is a blast nozzle, which directs the high-speed flow of abrasive material onto the surface. Nozzles come in different shapes and sizes depending on the media and desired coverage. They are typically made of wear-resistant materials like tungsten carbide or boron carbide due to the abrasive nature of the process.

Ancillaries

Laser Rust Removal: Key ancillary components include control software, safety enclosures, fume extractors, and protective optics. The software allows precise adjustments to beam parameters and patterns. Fume extraction is critical, especially when vaporized rust or coatings may release harmful particles or gases.

Sandblasting: Ancillaries for sandblasting include abrasive media hoppers, hoses, dust collectors, and personal protective equipment (PPE) like helmets and respirators. Modern setups often feature recycling systems to recover and reuse media, as well as containment booths to limit environmental contamination.

Mobility Options

Laser Rust Removal: Mobility varies by model. Some laser cleaning machines are compact and portable, with handheld wands and backpack-style units for fieldwork. Others are large, stationary systems designed for factory floors. Carts or wheeled enclosures add mobility, and robotic or CNC integration is common in industrial environments.

Sandblasting: Sandblasting systems are often trailer-mounted or skid-mounted for field deployment, particularly in construction or shipyard environments. Portable units allow flexibility but are bulkier and heavier due to the compressor and media storage. Hoses can extend reach, but equipment often requires a support team for setup and safety.

The architecture of laser rust removal systems centers around precision, control, and cleanliness, with optical components, electronics, and safety systems forming a compact, efficient machine. In contrast, sandblasting setups emphasize raw power and throughput, built around durable mechanical components capable of handling high volumes and rough environments.

The complexity, footprint, and support needs of each system reflect their intended use cases. Laser cleaning systems excel in controlled, technical applications where finesse is crucial, while sandblasting gear is built to take on large-scale, aggressive cleaning tasks. Choosing between them means weighing not just performance but the practicality of operating and maintaining the equipment in your specific context.

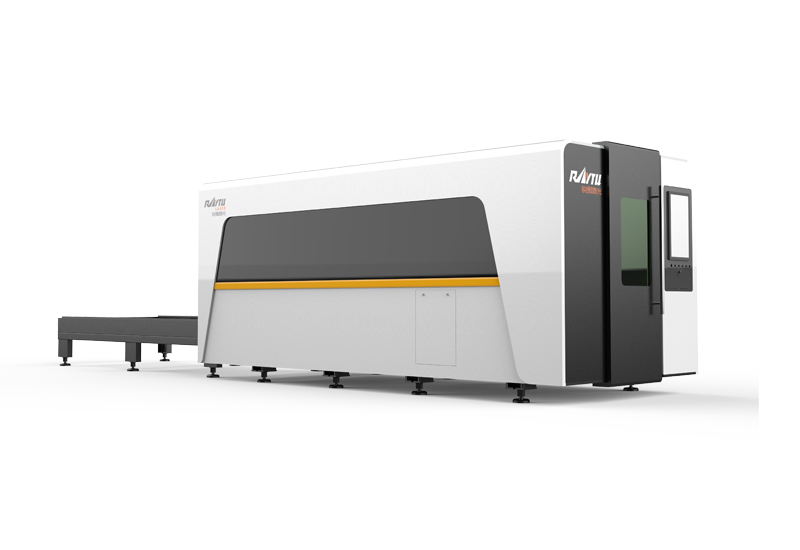

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

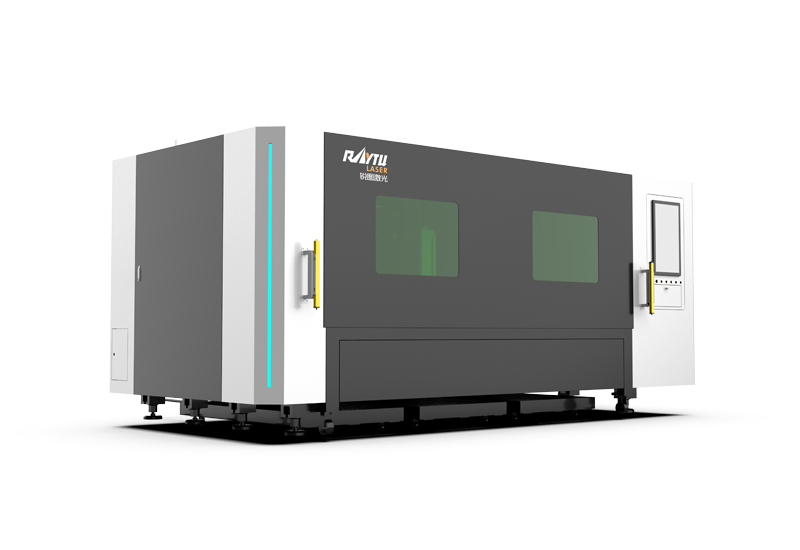

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

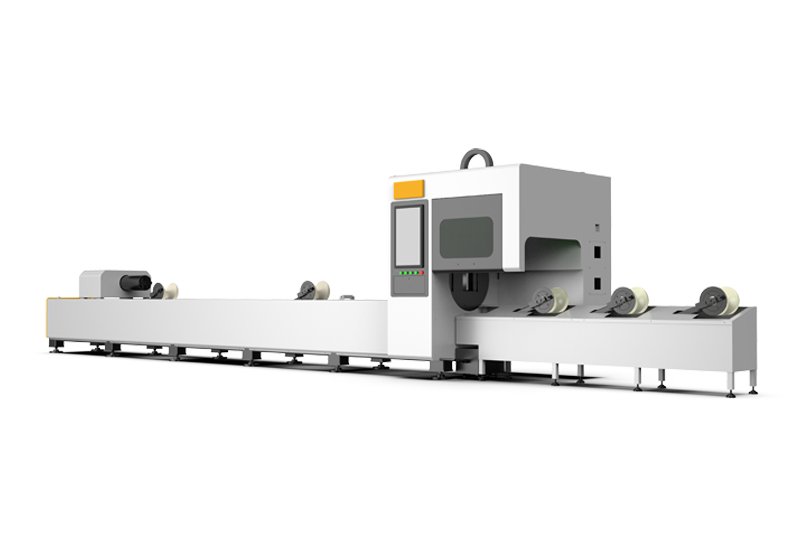

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

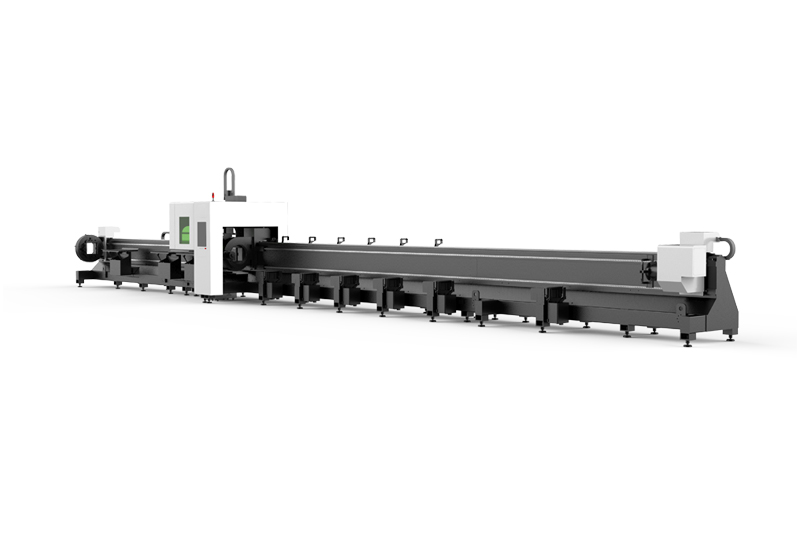

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR