When Gas Is Not Required

While shielding gas is essential in most laser welding scenarios, there are specific situations where it can be reduced or even eliminated. These exceptions are not the norm, but they exist—thanks to specialized environments, component design, or ultra-precise processes that control or eliminate exposure to air. In these cases, the need for shielding gas is replaced by alternative protective strategies such as vacuum conditions, physical barriers, or enclosure systems. Understanding when gas can be skipped safely is important for minimizing cost, simplifying setups, or addressing unique application constraints.

Vacuum Laser Welding (VLW)

Vacuum laser welding is performed inside a sealed chamber where air is completely removed, creating a low-pressure or high-vacuum environment. With no oxygen or nitrogen present, oxidation and atmospheric contamination are no longer a concern, removing the need for shielding gas. VLW is particularly useful for materials like titanium or magnesium that are extremely reactive at high temperatures. It also allows for precise welds with minimal porosity. The drawback is the cost and complexity of vacuum systems, which limits their use to high-value, low-volume applications such as aerospace components or scientific instruments.

Hermetic or Closed-Cell Welding

In some cases, components are designed to be self-shielding. For example, hermetic enclosures—such as battery cells, sensors, or sealed electronic modules—may be welded within a closed system where the internal atmosphere is controlled (e.g., inerted or evacuated). During the weld, the joint design and enclosure prevent outside air from reaching the weld zone. In these setups, external shielding gas may not be necessary. Precision is still critical, as the joint must be airtight, and any oxidation or contamination could compromise the entire sealed unit.

Micro-Welding Under Cover Slides

In micro-welding applications—such as bonding small sensors, optical components, or MEMS devices—laser energy may be applied through a transparent cover slide or encapsulation layer. The weld zone is physically isolated from air, which can reduce or eliminate the need for shielding gas. This technique is common in medical and electronic packaging, where minimal heat input and extreme precision are required. The sealed environment under the slide acts as a natural barrier to contamination. However, this only works for small-scale applications with tight control over materials and conditions.

While shielding gas is vital in most laser welding processes, certain controlled or enclosed environments can eliminate the need for it. Vacuum laser welding removes atmospheric gases entirely, closed-cell designs block external air, and micro-welding under cover slides offers passive protection. These cases are exceptions, not standard practice, and typically involve specialized equipment or part designs. Knowing when you can safely skip shielding gas—and when you absolutely can’t—is key to making smart, application-specific decisions.

Environmental and Economic Considerations

While shielding gas is often essential for laser welding, its use carries both environmental and economic consequences that manufacturers can’t afford to overlook. From the extraction and delivery of gases to their long-term operating costs, gas use introduces both resource demands and carbon footprints. At the same time, process inefficiencies—such as overuse, leakage, or improper gas selection—can quietly erode profitability and sustainability. Balancing performance with responsibility means weighing the real-world costs and environmental impact of gas usage in your laser welding process.

Environmental Impact

Shielding gases like argon, helium, and nitrogen are naturally occurring, but their industrial production, purification, compression, and transport require significant energy. Helium, in particular, is a finite resource extracted during natural gas processing and is increasingly expensive and scarce. Excessive or wasteful use contributes to unnecessary emissions and resource depletion.

In high-volume manufacturing, minimizing gas usage can significantly reduce a facility’s environmental footprint. This is especially relevant for companies striving to meet ESG (Environmental, Social, and Governance) goals or seeking certification for sustainable operations. Advanced gas delivery systems, process enclosures, and optimized flow rates can all contribute to lower consumption and cleaner operation.

Cost of Gases

Shielding gases vary widely in cost. Argon is generally affordable and readily available, making it a go-to for many applications. Helium, on the other hand, is costly and subject to supply fluctuations. Nitrogen is inexpensive, but only suitable for select materials. Misusing a high-cost gas when a lower-cost alternative would suffice leads to unnecessary expense.

In some cases, switching to gas mixtures or minimizing flow rates through better nozzle design and process control can lead to major savings without compromising weld quality. Manufacturers should evaluate total cost of ownership, factoring in not just the price per cylinder, but also flow rate, frequency of replacement, downtime for refills, and system maintenance.

Efficiency and Waste Reduction

Many welding operations overuse gas due to conservative settings, outdated equipment, or a lack of real-time monitoring. Flow meters, pressure regulators, and flow optimization software can help dial in the right amount of shielding for each application. Preventive maintenance—like inspecting for leaks, replacing worn nozzles, and calibrating gas delivery systems—can significantly reduce waste and lower operational costs.

Gas use in laser welding comes with real environmental and economic trade-offs. While necessary in most cases, it should be managed with efficiency and sustainability in mind. Choosing the right gas, using only what’s needed, and investing in proper equipment and maintenance can minimize both carbon impact and operational cost. In today’s competitive and environmentally conscious manufacturing landscape, responsible gas management is as much about performance as it is about long-term viability.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

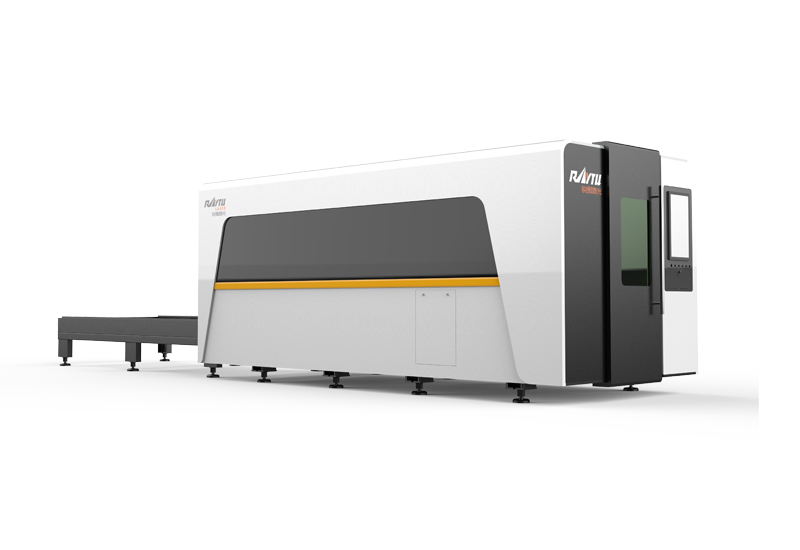

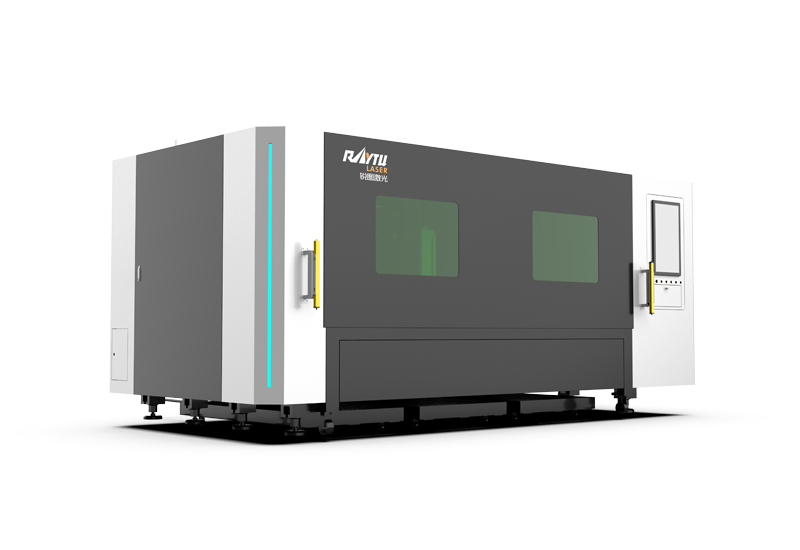

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

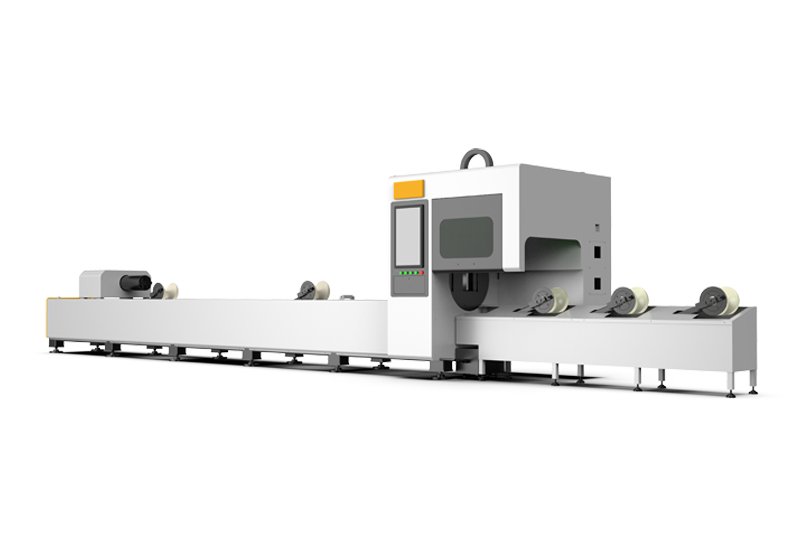

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

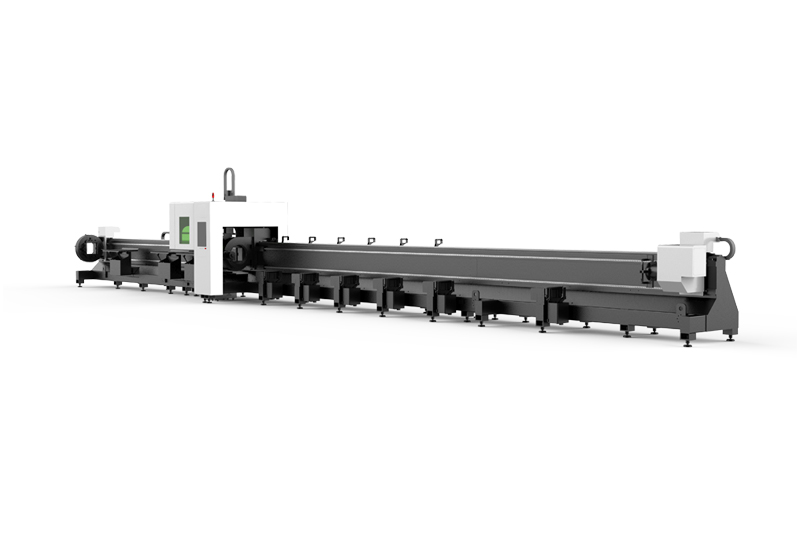

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR