Process Optimization

Shielding gas in laser welding isn’t just about choosing the right type or delivery method—how the gas is managed and maintained is just as important. Process optimization ensures the gas performs effectively, consistently protects the weld pool, and contributes to high-quality results. Poor gas control can lead to weld defects, surface contamination, and inefficient gas usage. Key optimization factors include volumetric flow rate, gas velocity, gas purity, and the condition of delivery hardware. Managing these variables is essential for maintaining stable welds and avoiding costly rework.

Volumetric Flow Rate

This refers to the amount of gas delivered per unit of time, typically measured in liters per minute (L/min). An inadequate flow rate can result in insufficient shielding, exposing the molten metal to atmospheric gases. On the other hand, an excessive flow rate may cause turbulence, pulling air into the weld zone and leading to contamination or porosity. Optimizing flow rate requires balancing the material type, welding speed, nozzle design, and joint configuration. Flow meters and pressure regulators are essential tools for keeping this parameter in check.

Gas Velocity

Velocity—the speed at which the gas exits the nozzle—affects how well the gas displaces air and maintains coverage over the weld pool. Too low, and the gas may not shield effectively; too high, and it may create turbulence or blow molten metal, causing weld irregularities. Unlike flow rate, velocity depends heavily on nozzle geometry and gas line pressure. Smooth, laminar flow is ideal, and test runs should be performed to fine-tune this parameter, especially when welding sensitive or thin materials.

Moisture & Purity

Even trace levels of moisture or impurities in the shielding gas can severely affect weld quality. Water vapor and contaminants like hydrocarbons or oxygen can cause porosity, discoloration, and even embrittlement in reactive materials. For high-spec industries such as aerospace or medical device manufacturing, using ultra-high-purity gas (typically 99.999%) is critical. Inline gas purifiers and moisture traps may be necessary to maintain purity, especially in humid environments or when working with materials like titanium, where contamination is unforgiving.

Nozzle Wear

Nozzle condition is often overlooked but has a direct impact on gas coverage and distribution. Worn, deformed, or partially blocked nozzles can cause uneven gas flow, reducing shielding effectiveness and introducing variability into the weld. Regular inspection and replacement of nozzles are essential to maintain consistent performance. In automated systems, nozzle wear monitoring can be integrated as part of a preventive maintenance program to avoid unexpected drops in weld quality.

Optimizing shielding gas performance in laser welding is a combination of science and fine-tuning. It’s not just what gas you use, but how you deliver it, how clean it is, and how well your system maintains control over time. Paying attention to flow rate, gas velocity, purity, and equipment condition can significantly improve weld consistency, reduce defects, and increase overall process efficiency. For any operation that values reliability and repeatability, gas optimization is not optional—it’s essential.

Material-Specific Guidelines

Not all metals behave the same under a laser beam, and neither should your approach to shielding gas. The type of material being welded significantly influences whether gas is required, what type of gas to use, and how it should be delivered. Different metals have different thermal conductivities, reactivity levels, and weld pool dynamics. Matching your shielding strategy to the material is critical to achieving strong, defect-free welds. Below are detailed guidelines for handling various common and specialized materials.

Carbon & Low-Alloy Steel

These materials are relatively forgiving and can often be laser welded with minimal shielding. However, using an inert gas like argon is still recommended to prevent oxidation and maintain bead appearance. For higher-strength low-alloy steels, shielding becomes more important to reduce the risk of cracking or porosity. Flow rate and gas coverage should be consistent, especially in high-speed or deep-penetration applications. Side jets or coaxial nozzles typically suffice.

Stainless Steel

Stainless steel is more reactive than carbon steel, particularly with oxygen and nitrogen at elevated temperatures. Argon is the go-to shielding gas for most stainless steel welding, offering clean, oxidation-free welds. For thicker sections or higher power welding, a helium-argon mixture can improve penetration. Nitrogen can also be used for austenitic grades to enhance corrosion resistance, but only in tightly controlled environments. A trailing shield is often used to protect the hot metal as it cools, especially for cosmetic or hygiene-sensitive applications.

Aluminum & Magnesium

Both metals are highly conductive and prone to oxidation, making proper gas shielding essential. Argon is typically used, although helium or helium-rich mixtures are preferred for thicker sections due to their ability to transfer more heat. Magnesium is even more reactive than aluminum and may require additional shielding or trailing gas to prevent oxidation and burn-through. Nozzle placement and flow control are critical here—too much velocity can create turbulence, while too little allows air contamination.

Copper & Precious Metals

Copper has high reflectivity and thermal conductivity, which makes laser welding challenging. Helium is often preferred due to its high ionization potential and better heat transfer, which helps achieve sufficient penetration. For precious metals like gold, silver, and platinum, shielding gas also helps prevent oxidation and discoloration. Given the value of the material, even minor defects can be costly. A coaxial nozzle and carefully controlled flow are standard, with ultra-clean gas to avoid contamination.

Titanium & Reactive Alloys

Titanium, zirconium, and other reactive metals are extremely sensitive to air exposure at high temperatures. Even brief contact with oxygen or nitrogen can ruin a weld, leading to embrittlement, porosity, or surface contamination. These materials require shielding gas—typically high-purity argon—and often use both primary and trailing shields. In some cases, an enclosed or inerted chamber is used for critical welds. Gas purity (99.999% or higher) is essential, and special attention must be paid to moisture and nozzle condition.

There is no universal rule for gas use in laser welding—it depends entirely on the material. Carbon steels may allow some flexibility, but reactive metals like titanium demand rigorous shielding. Choosing the right gas and delivery system, and tailoring them to the material’s properties, is the difference between a clean, strong weld and one riddled with flaws. Material-specific guidelines aren’t just recommendations—they’re requirements for success.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

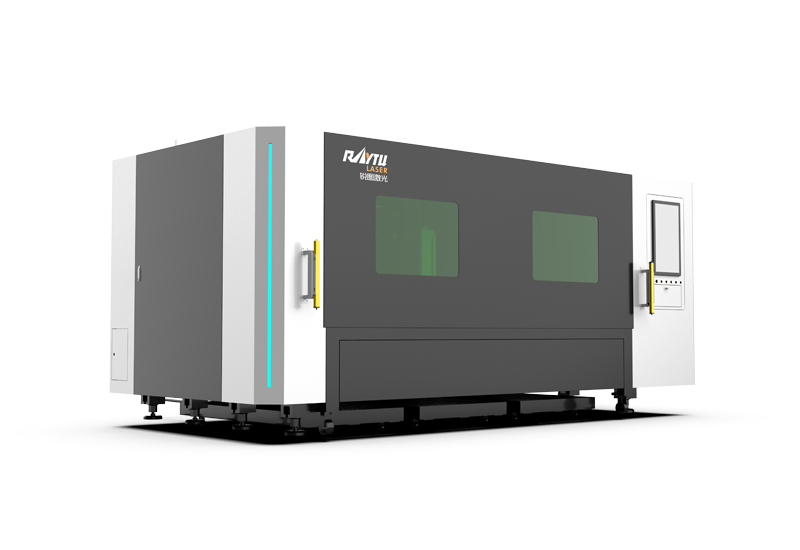

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR