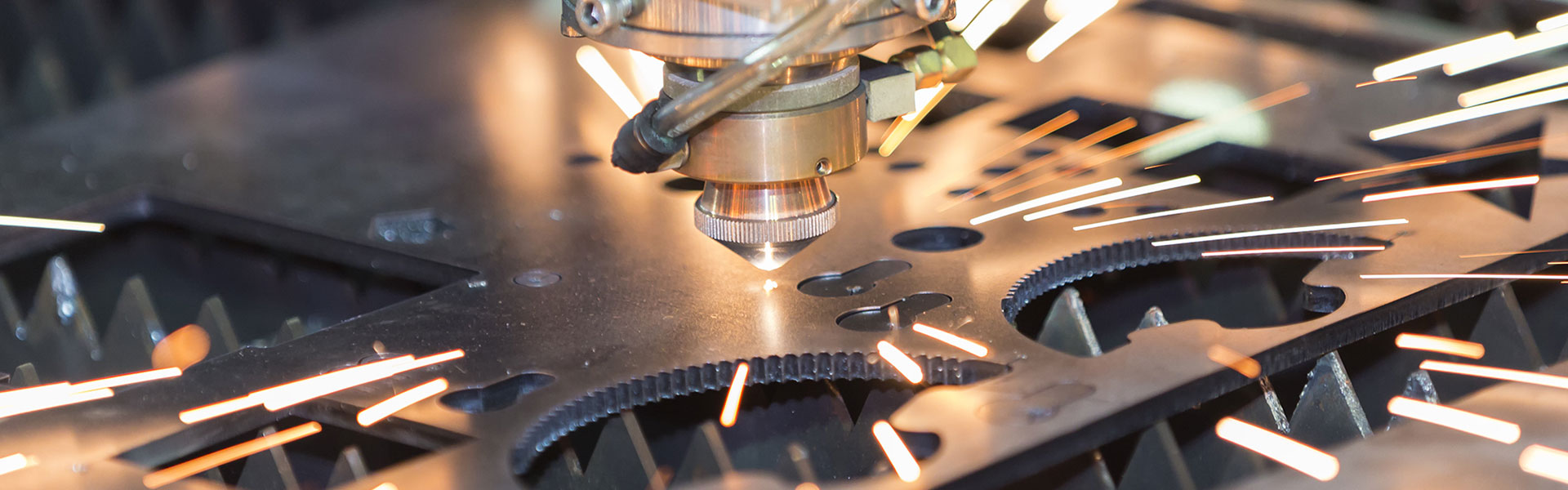

Material Compatibility and Thickness Range

One of the most critical factors in choosing between laser cutting and plasma cutting is how well each method handles different materials and thicknesses. While both are capable of cutting a wide range of metals, their performance varies significantly depending on the type, thickness, and intended finish of the material. Understanding these differences is essential for selecting the most efficient and cost-effective cutting process for a specific application.

Laser Cutting

Laser cutting excels at cutting thin to medium-thickness materials with exceptional precision. It is especially effective on:

Mild steel (up to ~25 mm with high-power lasers)

Stainless steel

Aluminum

Brass and copper (with fiber lasers, which are better suited to reflective metals)

Lasers can also cut non-metallic materials like wood, acrylic, and plastics, giving them broader application in industries like signage, electronics, and precision manufacturing. However, as material thickness increases—particularly beyond 20–25 mm—the speed and efficiency of laser cutting drop, and the cost of high-powered lasers increases significantly.

Plasma Cutting

Plasma cutting is built for power and thickness. It works best on:

Mild steel

Stainless steel

Aluminum

Plasma can easily handle material thicknesses up to 50 mm or more, depending on the system. While it doesn’t match laser cutting in precision or edge finish, it outperforms in cutting speed and cost-effectiveness when working with thick or large metal plates. However, plasma is limited to electrically conductive materials and is not suitable for non-metals or highly detailed work.

Laser cutting is the go-to choice for thin to medium materials where precision, fine detail, and edge quality matter. Plasma cutting dominates in heavy-duty scenarios, offering speed and affordability for thicker metals. Choosing the right process hinges on knowing the material type, desired thickness range, and the level of detail required. Matching the cutting method to the material ensures both quality results and efficient production.

Cutting Quality and Precision

When evaluating cutting technologies, quality and precision are just as important as speed and cost. The final cut impacts downstream processes like welding, fitting, and finishing, making factors like dimensional accuracy, kerf width, heat-affected zone (HAZ), and edge quality critical in choosing between laser and plasma cutting. Each method produces distinctly different results, and the differences can significantly influence product consistency and post-processing requirements.

Dimensional Accuracy

Laser cutting delivers high dimensional accuracy, typically within ±0.1 mm or better, thanks to its fine, focused beam and precise CNC control. This makes it ideal for applications requiring tight tolerances and repeatability, such as aerospace components, electronics, and fine mechanical parts. Plasma cutting, while accurate, generally maintains tolerances around ±0.5 mm depending on the equipment and operator skill. It’s well-suited for structural or industrial parts where extreme precision is not essential.

Kerf Width

The kerf—the width of the cut—differs between the two methods. Laser cutting produces a narrow kerf, often between 0.1 mm and 0.5 mm, which allows for tight nesting of parts and minimal material waste. Plasma cutting, on the other hand, has a wider kerf, typically ranging from 1 mm to 3 mm, which limits part density on a sheet and may result in more material loss.

Heat-Affected Zone (HAZ)

Laser cutting generates a relatively small heat-affected zone due to the precision and controlled energy input of the beam. This minimizes the risk of warping or altering the mechanical properties of the surrounding material. Plasma cutting, by contrast, produces a larger HAZ due to higher thermal input and a broader arc. While modern plasma systems have reduced this effect, the heat can still impact metallurgical integrity and require additional processing in sensitive applications.

Edge Squareness & Roughness (Ra)

Laser cutting typically provides clean, square edges with minimal dross and a low surface roughness (Ra), often under 3.2 µm. It’s well-suited for parts that require minimal post-processing. Plasma cutting, while improved over earlier systems, usually produces slightly beveled or rougher edges, with Ra values ranging from 6.3 µm to 25 µm depending on the thickness and speed. This may require secondary finishing in precision-critical projects.

Laser cutting leads the way in quality and precision, offering superior edge definition, tighter tolerances, and minimal thermal distortion. Plasma cutting, though less refined, is still effective for general fabrication where speed and cost are prioritized over fine detail. Ultimately, the choice depends on the required finish quality, tolerance levels, and the complexity of the part. For high-precision work, laser is the clear choice; for thicker, less detail-sensitive projects, plasma remains a reliable option.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

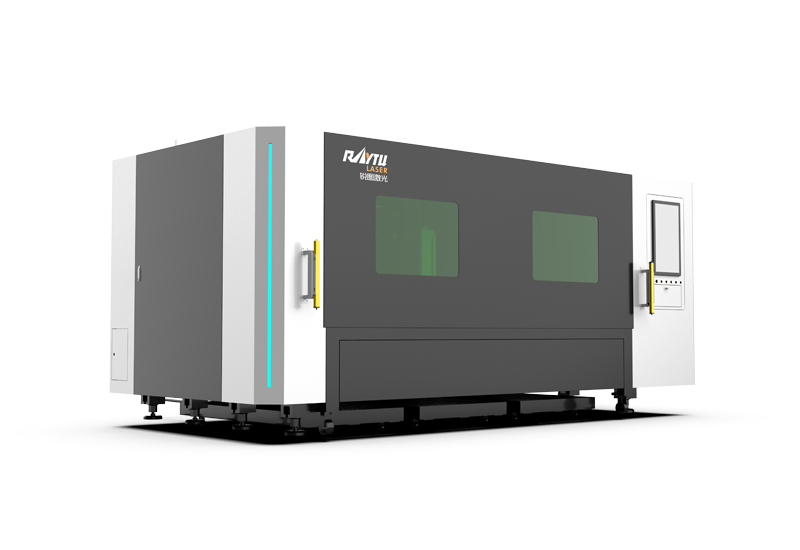

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR