Fundamentals of Cutting Technologies

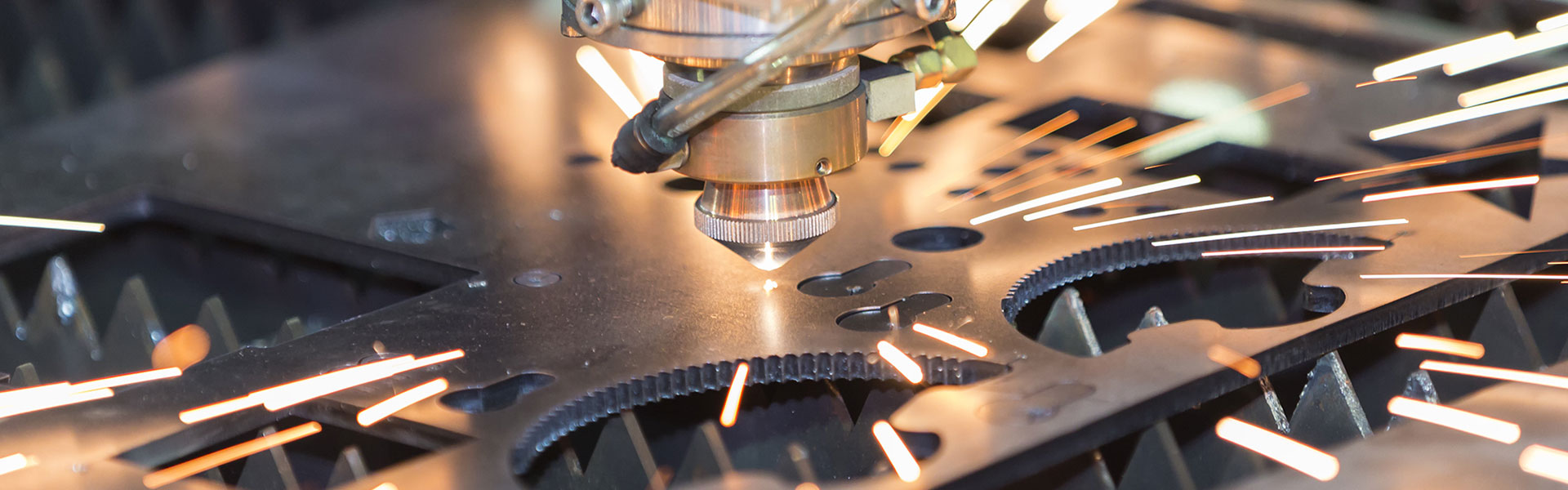

To compare laser cutting and plasma cutting effectively, it’s essential to understand the core mechanics behind each method. While both are thermal cutting processes designed to shape and separate metal, they operate using different technologies and physical principles.

Principles of Laser Cutting

Laser cutting uses a concentrated beam of light to melt or vaporize material along a specific path. The laser beam—generated by a CO2, fiber, or crystal source—is directed through a focusing lens to a fine point on the material’s surface. A high-pressure assist gas, such as nitrogen or oxygen, expels the molten material, creating a precise and narrow cut. The process is digitally controlled, delivering clean edges, high repeatability, and the ability to handle fine, intricate designs, especially in thinner materials.

Principles of Plasma Cutting

Plasma cutting relies on generating a high-temperature plasma arc by sending an electrical current through a compressed gas, typically air or nitrogen. This plasma arc reaches temperatures of over 20,000℃, instantly melting the metal. The force of the gas blows the molten metal away, forming the cut. Plasma cutting is highly effective for thicker materials and conductive metals such as steel, stainless steel, and aluminum. It’s faster than laser cutting at higher thicknesses and more adaptable for rough or on-site work due to the availability of portable hand-held units.

Historical Context and Evolution

Plasma cutting emerged in the 1950s as an innovation derived from TIG welding technology. It gained popularity in heavy industries by the 1970s for its speed and ability to cut thick metal that other methods struggled with. Laser cutting entered the scene in the late 1960s, initially limited by high costs and slower processing speeds. However, advances in CNC (computer numerical control), beam quality, and automation in the 1980s and 1990s rapidly improved its efficiency and precision. Today, both technologies are integral to modern fabrication, evolving alongside advancements in software, power sources, and materials.

Laser and plasma cutting have distinct origins, operating principles, and strengths that make each suited to specific industrial needs. Laser cutting stands out for precision and finesse, while plasma cutting excels in speed and handling thicker, tougher materials. Understanding the fundamentals of these technologies not only clarifies how they work but also highlights why the choice between them matters in terms of performance, cost, and final product quality.

Equipment and Core Components

Behind every clean cut or precise edge in metal fabrication is a highly engineered system made up of several key components. Both laser and plasma cutting systems rely on specialized equipment tailored to their cutting method, but their setups differ significantly in design, function, and integration potential. Understanding the architecture of these systems—and how they adapt to modern automation—gives valuable insight into operational costs, performance capabilities, and long-term scalability.

Laser Cutting System Architecture

A typical laser cutting system includes the following core components:

Laser Source: Generates the laser beam. Common types include CO2, fiber, and crystal lasers.

Beam Delivery System: Mirrors or fiber optics guide the beam from the source to the cutting head.

Focusing Optics: Lenses concentrate the beam to a fine point for precision cutting.

Assist Gas System: Delivers oxygen, nitrogen, or air to blow molten material out of the kerf and improve edge quality.

CNC Controller: Governs the movement of the cutting head and table, allowing for complex, high-accuracy cuts.

Cutting Table: Holds the workpiece and may include fume extraction and support slats for stability.

Laser systems are generally enclosed, with safety features to protect operators from exposure to the high-powered beam.

Plasma Cutting System Architecture

Plasma cutting setups include:

Power Supply: Converts electrical energy to support the plasma arc.

Plasma Torch: Houses the electrode and nozzle where the arc forms and the gas is ionized.

Gas Supply: Provides compressed air or other gases like nitrogen or argon to create and maintain the plasma.

CNC Controller or Manual Operation: Depending on the application, the system may be manually operated or CNC-controlled for automated production.

Work Table or Workbench: Supports the metal being cut and often includes water beds or downdraft systems to manage fumes and debris.

Plasma systems tend to be more rugged and open, making them suitable for harsher industrial environments and field work.

Automation & Integration

Both cutting technologies have evolved to support high levels of automation. Laser cutting systems are typically integrated into fully automated production lines with robotic arms, material loading/unloading systems, and advanced software for nesting and path optimization. Plasma systems also support automation but are more commonly seen in semi-automated setups or combined with CNC plasma tables in fabrication shops. Integration with CAD/CAM software is standard in both systems, enabling streamlined workflows and faster turnaround times.

The equipment behind laser and plasma cutting reflects the strengths of each method—laser systems prioritize precision, cleanliness, and full automation, while plasma systems focus on speed, durability, and versatility. Knowing the core components and how each system is built helps decision-makers understand not just the cutting capability, but also the long-term investment in infrastructure, maintenance, and productivity.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

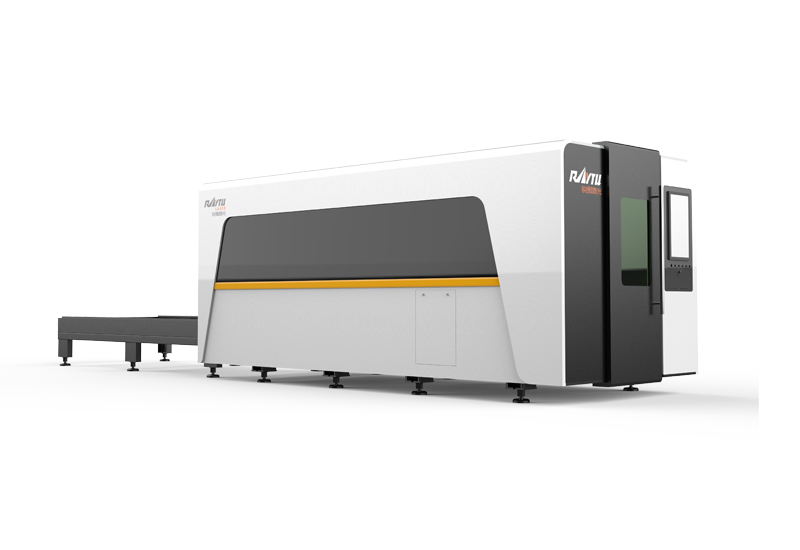

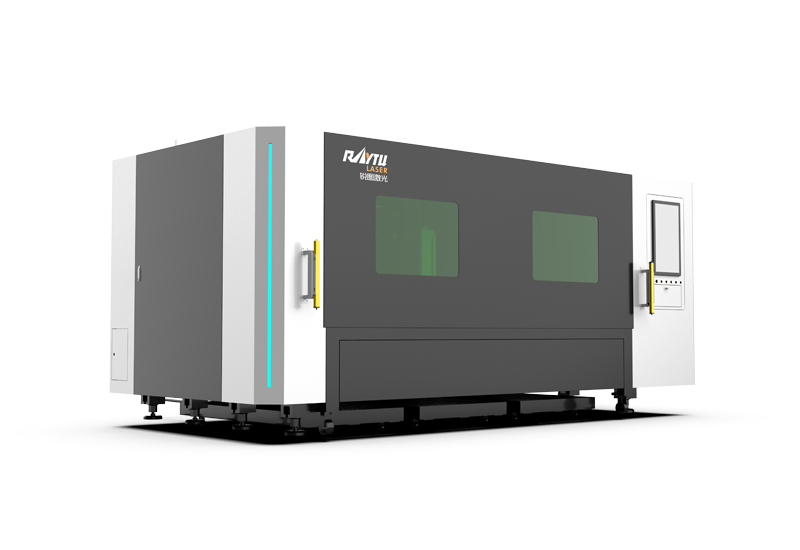

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

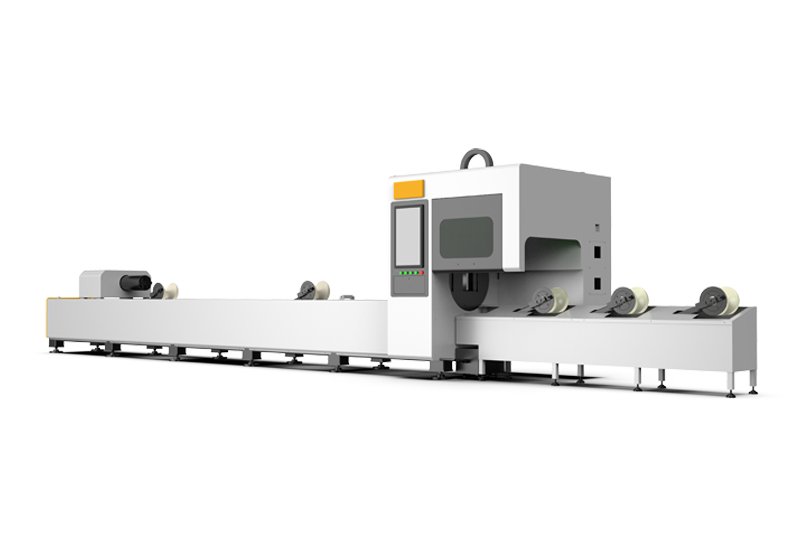

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

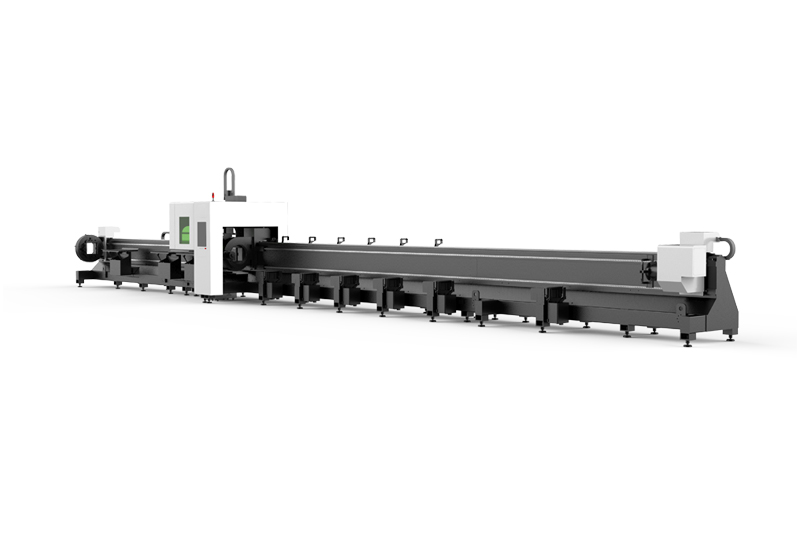

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR