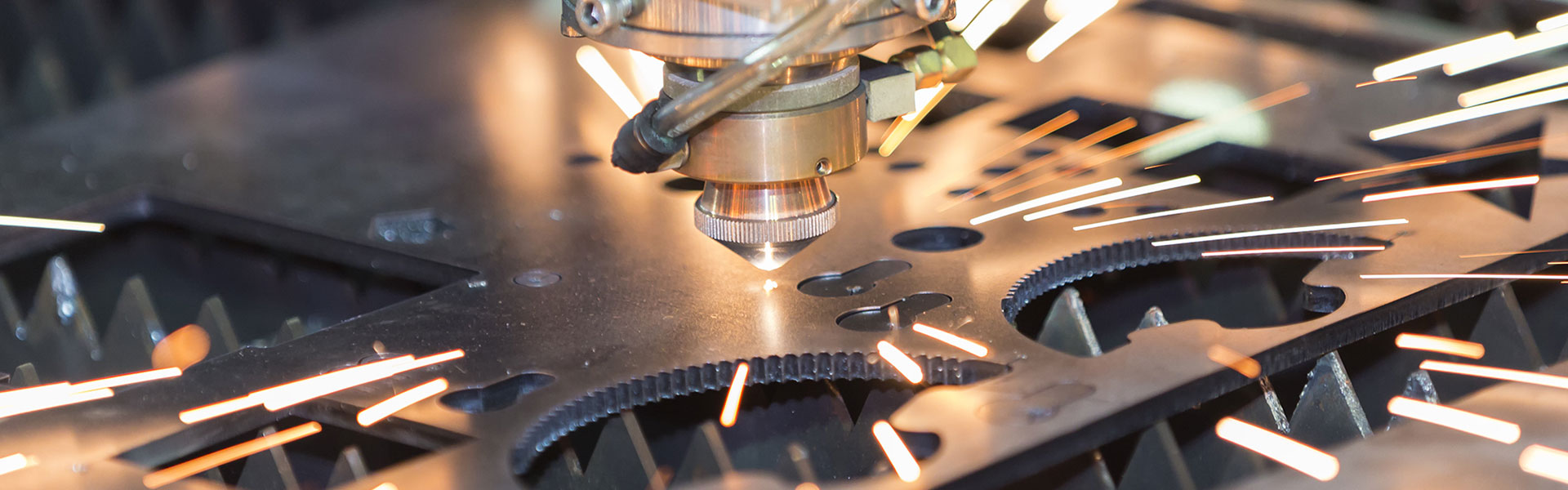

Laser cutting has revolutionized modern manufacturing by offering precision, efficiency, and versatility. Whether you're in the automotive industry, creative arts, or industrial fabrication, understanding laser cutter basics is essential. This guide provides a comprehensive introduction to laser cutting, covering its basics, different types, and benefits.

1. What is Laser Cutting?

Laser cutting is a technology that uses a focused laser beam to cut materials with high precision. The laser, typically controlled by a computer, directs the beam onto the material's surface, heating it until it melts, burns, or vaporizes, creating a clean, accurate cut.

How It Works: The process involves directing a high-powered laser beam onto the material. The intense energy of the laser causes the material to either melt, burn, or vaporize, depending on the material and the laser's power settings. This method allows for very precise cuts, even with intricate designs.

Applications: Laser cutting is used in various industries, from metal fabrication to custom signage, due to its ability to produce detailed, high-quality cuts. Understanding basic laser cutter operations is crucial for those entering fields where precision cutting is required.

2. Overview of Laser Cutter Types

Laser cutters come in different types, each suited to specific materials and applications. Knowing the basic laser cutter types helps in selecting the right machine for your needs.

CO2 Lasers: These are the most common types of laser cutters. They are ideal for cutting non-metal materials like wood, acrylic, and plastics. CO2 lasers are popular in industries like signage and woodworking.

Fiber Lasers: Fiber lasers are powerful and efficient, especially when cutting metals. They are widely used in industrial applications where high precision and speed are required. Getting started with a fiber laser cutting machine involves understanding its capabilities and the types of materials it can handle.

Diode Lasers: These are typically used for engraving and cutting thin materials. Diode lasers are less powerful but are suitable for small-scale projects or delicate materials like paper and fabric.

Understanding these laser cutting related information is crucial for anyone looking to get involved in the technology. Each type of laser cutter offers unique advantages, making it important to choose the right one based on the specific needs of your project.

3. Getting Started with Fiber Laser Cutting Machines

Getting started with a fiber laser cutting machine involves understanding its setup, operation, and maintenance. These machines are known for their precision and efficiency, especially when cutting metals.

Initial Setup: Begin by carefully positioning the machine in a well-ventilated area. Ensure it is on a stable surface and connected to a reliable power source. Proper ventilation is crucial because laser cutting can produce fumes and small particles.

Safety First: When operating the machine, always wear proper safety gear. This includes protective glasses. Familiarize yourself with the machine's safety features. Such as emergency stops and ventilation systems.

Calibration and Testing: Before starting your first project, calibrate the machine according to the manufacturer's instructions. Perform a few test cuts on scrap material before using it.

Understanding these laser cutting related information helps in setting up your machine efficiently, ensuring accurate cuts right from the start.

4. Core Components of a Laser Cutter

A basic laser cutter consists of several key components, each playing a vital role in the machine’s operation.

Laser Source: The heart of the machine, the laser source generates the beam that cuts through materials. In fiber laser cutting machines, this source is typically a fiber optic laser known for its precision and efficiency.

Cutting Head: The cutting head directs the laser beam onto the material. It includes lenses and mirrors that focus the beam precisely where it’s needed. The cutting head also often has an assist gas nozzle, which helps to blow away molten material during the cutting process.

CNC Controller: This is the brain of the machine, controlling the movement of the cutting head and the laser beam according to the design input. The CNC controller ensures that the laser follows the exact path needed to create the desired cuts.

Worktable: The worktable is where the material is placed during cutting. It needs to be sturdy and stable, as any movement can affect the precision of the cut.

Understanding these components is crucial for maintaining your machine and ensuring it operates smoothly. Regular maintenance of these parts will prolong the machine’s lifespan and maintain cutting accuracy.

High Power Fiber Laser Cutting Machine

High Power Fiber Laser Cutting Machine

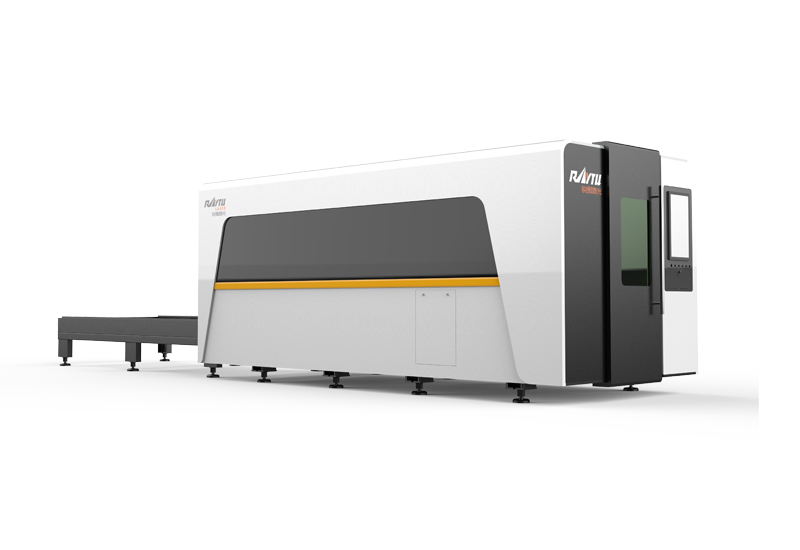

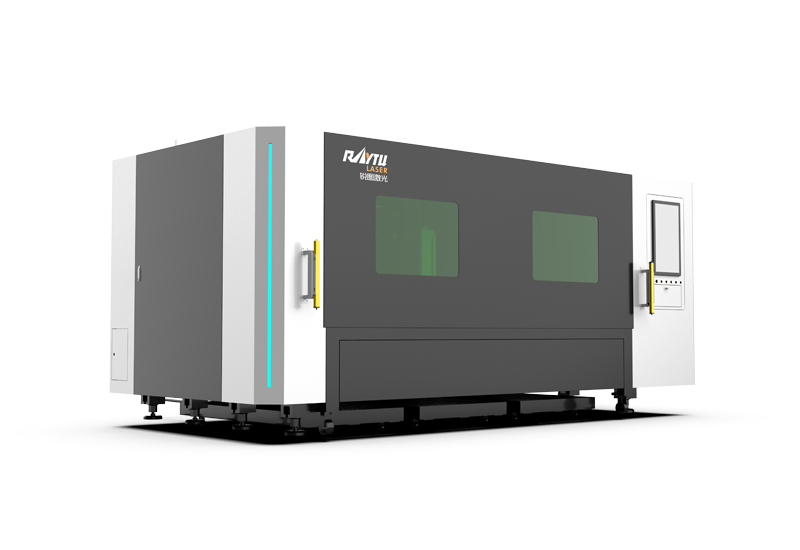

Enclosed Fiber Laser Cutting Machine

Enclosed Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

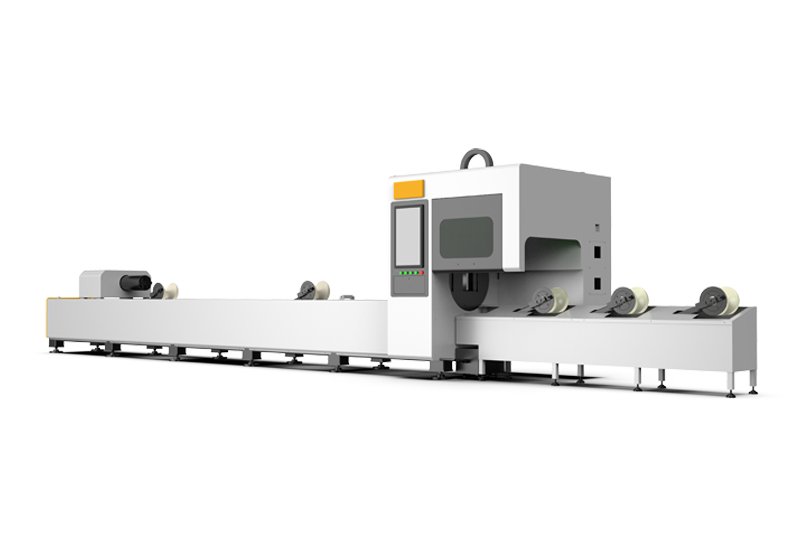

Automatic Tube Laser Cutting Machine

Automatic Tube Laser Cutting Machine

Coil Fiber Laser Cutting Machine

Coil Fiber Laser Cutting Machine

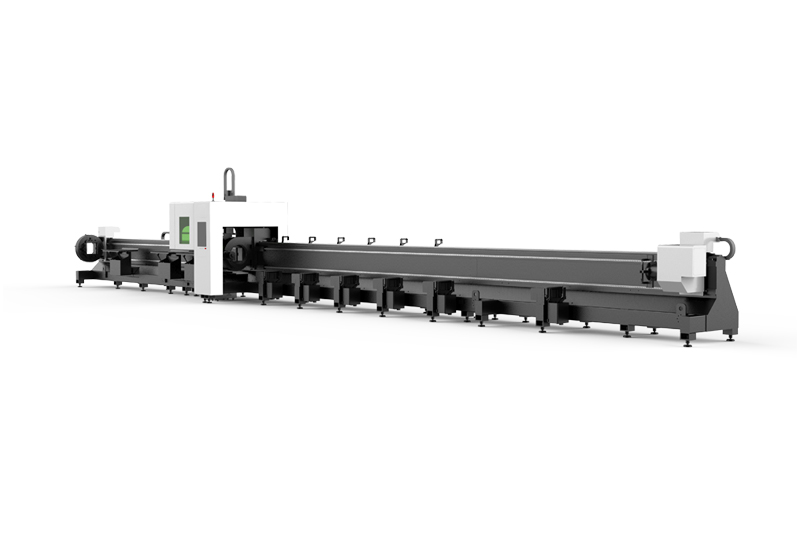

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

RTC-12036M 3 Chucks Tubeeber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

Single Table Enclosed Fiber Laser Cutting Machine

EN

EN ES

ES RU

RU AR

AR